Overview of Heat-Resistant Steel

Definition and Classification

Heat resistant steel, also known as high-temperature leather steel, is a special engineering alloy designed specifically for operation in high-temperature environments. This material can withstand continuous thermal loads while maintaining its mechanical properties and structural stability. Our heat-resistant steel products are manufactured using advanced alloy technology, ensuring excellent performance and long-lasting durability even in the most demanding applications.

| Name | Characteristics |

| Ferritic Heat Resistant Steel | Contains chromium; good resistance to oxidation; moderate strength |

| Austenitic Heat Resistant Steel | High nickel content; excellent corrosion resistance; superior ductility |

| Martensitic Heat Resistant Steel | High carbon content; excellent hardness; moderate corrosion resistance |

Importance in Industrial Applications

The significance of heat steel, in settings cannot be emphasized enough. Its pivotal role is evident in industries with high-temperature operations. This specific steel type guarantees the durability and security of components subjected to pressures resulting in lower maintenance expenses and averting disastrous breakdowns. Sectors like aerospace, automotive, petrochemical, and energy production heavily depend upon heat steels, for their activities.

Key Properties of Heat Resistant Steel

High-Temperature Characteristics

One key feature of heat steel is its capability to maintain its strength, at high temperatures. This quality is essential for uses such as turbine blades and exhaust systems that endure heat. The addition of alloying elements like chromium, nickel, and molybdenum plays a role, in improving these characteristics by creating phases that can withstand deformation when exposed to thermal stress.

Physical Properties

Steels that can withstand temperatures have a set of qualities that make them ideal, for tough conditions.

Chemical Stability

Heat-resistant steel is also known for its ability to maintain its composition when exposed to temperatures and corrosive substances, in settings like chemical processing plants due to the presence of elements such, as chromium and aluminum that prevent oxidation and corrosion.

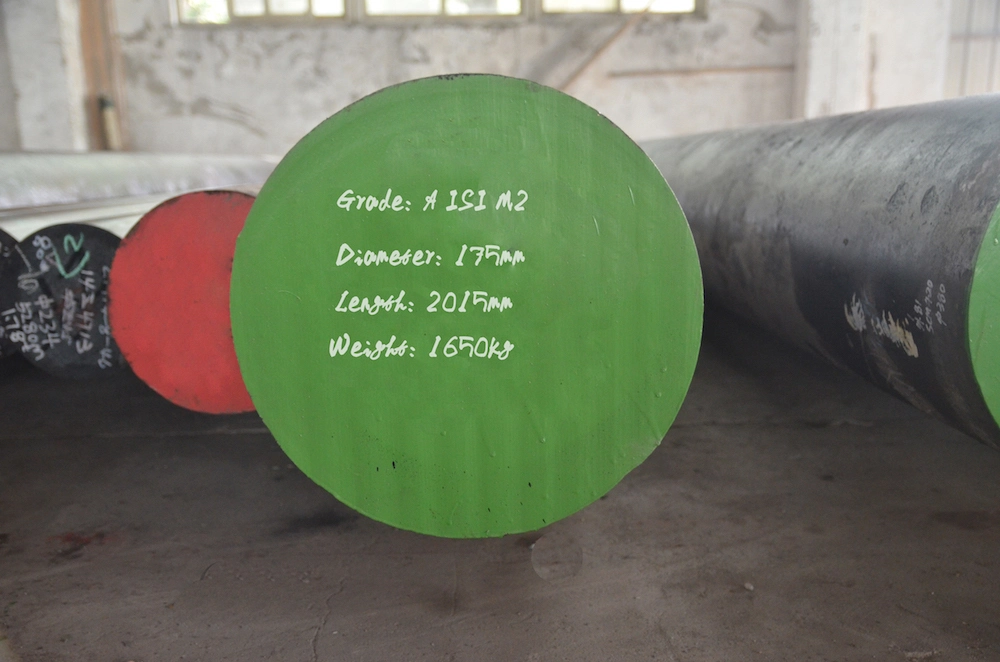

Machinability and Fabrication

Heat-resistant steels may be strong and durable. Are also engineered to be worked with using common industrial methods, for shaping and assembling parts efficiently in demanding high-temperature settings. They are versatile, for producing forms and elements needed in applications that require heat resistance. Enhancing their workability involves managing the alloy ingredients to facilitate cutting, welding, and shaping while preserving the material’s characteristics.

Applications of Heat Resistant Steel

Various industries rely heavily upon heat steel, for its capability to endure temperatures without compromising its structural integrity making it an essential component in a wide array of applications, within different sectors.

Pressure Vessels

In the world of pressure containers and tools making, heat resistant steel is a favored material because of its toughness and longevity, in temperature and high-pressure settings. These containers are heavily utilized in sectors, like chemical processing, oil and gas production, and power generation. Typically holding liquids or gases at increased pressures the employment of heat steel guarantees their operation without concerns of structural damage caused by heat stress or rust. These steels are perfect, for building pressure vessels that adhere to safety regulations due to their resistance, to oxidation and ability to maintain mechanical integrity even in harsh environments.

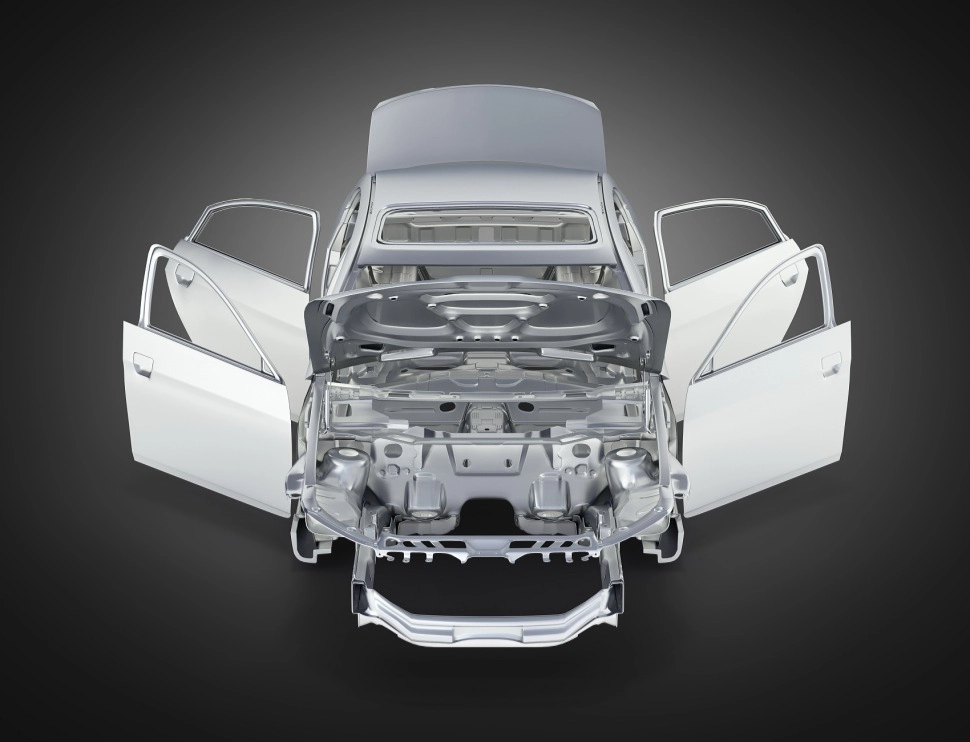

Automotive Industry

Automative manufacturing industry sees advantages in employing heat steel for parts exposed to intense heat, like exhaust systems and turbochargers in vehicle engines. This type of steel’s ability to withstand temperatures ensures it can handle the changes during vehicle use without deteriorating. This durability does not boost the effectiveness and productivity of auto components. Also helps lessen emissions by maintaining optimal performance, over long durations.

Aerospace Sector

The aerospace industry requires materials that can withstand conditions, with consistency; hence heat resistant steel plays a role in aircraft production processes. Turbine blades, tailpipe casings, and other parts materials can endure temperatures and mechanical strains experienced during flights. The exceptional ability of heat steels to withstand deformation and chemical reactions makes them ideal for these purposes, safeguarding safety and effectiveness in aerospace activities. Additionally, the ease of machining heat steels enables the precise crafting of components crucial, for aerodynamics and fuel efficiency enhancement.

Energy Sector

Heat-resistant steel is essential, in the energy industry for both sustainable energy generation purposes. Power stations utilize fossil fuels or nuclear resources to generate electricity. Boilers and turbines at temperatures. Heat-resistant steel is crucial for maintaining operational efficiency over extended durations without being affected by thermal wear or corrosion. Moreover in energy setups such, as thermal plants using receivers and heat exchangers to boost energy absorption and transformation efficiency.

Petrochemical Industry

The field of petrochemicals includes procedures that run at temperatures and handle materials. Having heat steel is crucial, for building tools like reactors and pipelines that need to endure conditions. The addition of metals like chromium enhances the durability of these steels making them resistant to rust and capable of retaining their structure in extreme chemical environments. This toughness plays a role in maintaining operations without the need, for servicing or part replacements.

In summary of the discussion, The distinct features of heat steel contribute significantly to its widespread use, in various industries that frequently involve high-temperature processes. Its uses span from guaranteeing safety in pressure containers to boosting efficiency in car engines and ensuring durability, in aerospace parts. Through harnessing the qualities of this material industries can enhance productivity and safety standards while reducing maintenance expenses and operational interruptions.

Promispecial is a leading manufacturer and distributor of high-quality steel products designed to meet the demanding needs of various industries. With a commitment to innovation and excellence, Promispecial offers a wide range of alloy steels that are engineered to provide superior performance in challenging environments.