Evolution of Carbon Spring Steel

Spring steel evolved thousands of years ago to cater to the requirements of industries. At first, the main goal was to develop simple mechanical properties for basic uses. It has been improved over time as metallurgical and production processes have become more advanced allowing for more complicated and robust applications. Carbon spring steel has undergone various tests through the years in the name of upgrading the materials to where the properties of higher resistance against deformation, strength, elasticity, and fatigue are possible.

| Grade | Application |

| 65, 70, 80, 85 | Widely used in various applications, carbon spring steel is particularly suitable for small springs operating at low temperatures or larger springs that are not highly critical. |

| 65Mn, 70Mn | It is commonly employed in the production of small-section flat springs, round springs, clock springs, spring rings, valve springs, shock absorber springs, clutch springs, and brake springs. |

Role of Carbon Content in Spring Steel

Carbon Content in Spring Steel Spring Steel contains a relatively high % of % of carbon. With a carbon content that generalises between 0.60% and 0.90 %, and because of this, it gives the steel its hardness and strength. More carbon imparts increased tensile strength and wear resistance but decreases ductility. As a result, choosing the correct carbon percentage is a linchpin between the right balance of power and compression, depending on the application.

Characteristics of Carbon Spring Steel

Metallurgical Quality

Excellent metallurgical quality is inherent in the exceptional purity and homogeneity of high-quality carbon spring steels. This guarantees long-lasting reliable service in a variety of use cases. During production, the steel undergoes extensive refinement to remove impurities, such as sulfur and phosphorus, that could negatively affect mechanical properties. This yields a material with very stringent requirements concerning surface quality and dimensional tolerances.

High Tensile Strength

Carbon spring steel has earned a reputation for its high tensile strength; it can carry a lot of weight without bending. This property is important for applications where applications experience stress and need to last, for example, automotive suspension systems and industrial machinery springs. This combination of low carbon content, coupled with closely controlled heat treatment procedures enables high tensile strength properties to be attained.

High Elasticity

If the load applied to carbon spring steel stays within a certain limit, it can deform elastically, meaning that once the load is removed, no permanent damage is done. This is a vital characteristic of springs operating in dynamic environments, requiring them to be able to absorb repeated shocks and vibrations while retaining their original shape and functionality. This characteristic is very important for springs that operate in a dynamic environment where they will be subjected to repeated shock and vibration and must hold their form and function.

High Fatigue Strength

Cyclic loads require good fatigue strength over the life of the part and this is one of the key properties of carbon spring steel. This property gives it the ability to be used in applications that experience permanent stress variation like valve springs in an engine or precision springs in aerospace components. Metallurgical heat treatment processes are required to tailor the microstructure of the material to achieve the desired high fatigue strength.

Key Production Techniques for Carbon Spring Steel

Material Selection

Promispecial selects suitable raw materials is the first step in the production process of carbon spring steel. Its carbon content is normally between 0.60% – 0.90%, with the specific combination selected so mechanical qualities, tensile strength, firmness, etc., are as desired. Manganese content ranges as well, helping to improve both hardenability and wear resistance and thereby improving performance.

Melting and Refining Processes

Select raw materials are melted in an electric arc furnace (EAF) or basic oxygen furnace (BOF) to produce carbon spring steel. This stage is polishing to get rid of these impurities such as sulphur and phosphorus further providing a higher purity and uniformity. This results in the steel showing refined fatigue risk, which is important, along with mechanical properties, in severe applications.

Casting Methods

After the molten steel is refined, it is poured into billets, blooms, or slabs in either continuous or ingot casting. Continuous casting is an efficient method that produces steel with uniform properties on a part-per-million scale in a continuous form of hundreds of tonnes. This way of working guarantees an output ready to be processed. This way you will provide a high-quality output image for generating proper next processing steps.

Heat Treatment Procedures

The heat treatment process is an important step for obtaining the axial properties of carbon spring steel. They require high heating temperatures where the steel is austenitized between 800°C and 900°C and oil or water quenched to obtain a martensitic structure. Later, tempering between 300 °C to 500 °C makes it less brittle but increases toughness and elasticity achieving a good compromise of strength and ductility.

Surface Treatment Techniques

This procedure is followed for treating the carbon spring steel to dust off the rough edge to retain a quality surface finish. These are shot blasting, pickling, phosphating, zinc coating, etc. Surface anomalies like decarburization are thoroughly checked and corrected for strength and consistency. Decarburization is one of the surface defects that are carefully checked and eliminated to prevent durability and reliability issues.

Inspection Protocols

We have stringent inspection procedures to ensure carbon spring steel conforms to the strict specifications. Quality control tests: dimensional testing, hardness, tensile strength, and fatigue testing. Non-destructive testing methods such as ultrasonic, and magnetic particle inspection are used for the detection of internal and surface defects. Methods such as ultrasonic or magnetic particle inspection to check for internal and surface defects in such cases can be classified as non-destructive tests that make sure only the best products are marketed.

Applications of Promispecial Carbon Spring Steel

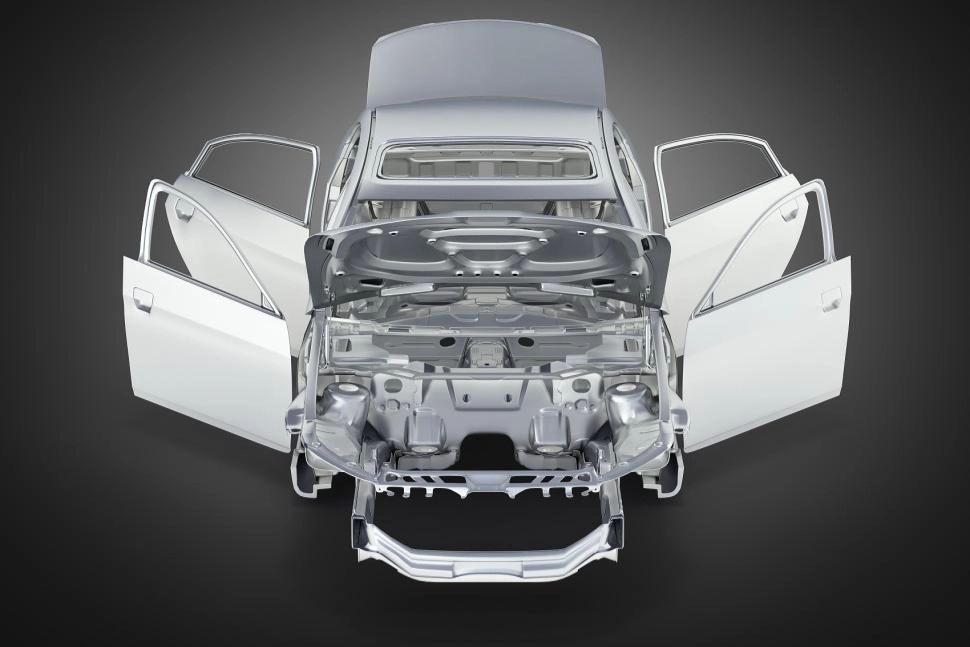

Automotive Industry

Promispecial High-quality carbon spring steel plays an essential role in the automotive sector, as it is used to make suspension springs and valve components. These components need to be able to endure a lot of stress and still be reliable in time. Its high tensile and fatigue properties give this material the necessary properties for usage in these critical components thereby enhancing both the safety and performance of the vehicle. Due to the high tensile strength and fatigue resistance of the material, this critical component plays a very important role in vehicle safety and performance.

Industrial Machinery

Due to its ability to withstand heavy loads, carbon spring steel can be found in industrial machinery. Springs from this substance offer an assured performance in tough conditions, where long-lasting use is of utmost importance. The shock and vibration-proof capacity makes it an ideal material for machinery that requires continuous and stable operation. Essential for machines that need stability, its resistance to impact and vibration is practically vital.

Aerospace Sector

Aerospace is a highly demanding field that calls for materials working consistently under microgravity. This is where carbon spring steel excels, with outstanding elasticity and fatigue strength. Precision springs that should remain functional amidst changes in load and temperature, and, thus, can effectively optimize performance under extreme aerospace conditions. It finds utility in precision springs that also work under different loads and temperatures, which helps in maintaining performance even in challenging aerospace applications.