Why Alloy Spring Steel is Needed

Alloy Spring steel is a specialized material that is required to produce springs and elastic products possessing advanced mechanical properties and performance. This particular steel is designed to meet the high, rigorous needs of industries delivering high strength, durability, and reliability. Alloy Spring Steel- It is used for withstanding heavy loads without deformation, elasticity under stress, and better fatigue properties. Industries like automotive, construction, energy, and many others rely on it because of these properties.

| Table of Alloy Spring Steel Grades by Country | |||

| GB | ISO.683-14 | EN 10089 | JIS G 4801 |

| 38Si2 | 38Si7 | 38Si7 | — |

| 55CrMn | 55Cr3 | 55Cr3 | SUP9 |

| 60CrMn | 60Cr3 | 60Cr3 | SUP9A |

| 60CrMnMo | 60CrMo3-3 | 60CrMo3-3 | SUP13 |

| 55SiCr | 55SiCr6-3 | 54SiCr6 | — |

| 52CrMnMoV | 52CrMoV4 | 52CrMoV4 | — |

Key Elements Contributing to Performance

Silicon and Manganese

Silicon and manganese content are primary constituents of Alloy Spring Steel. Silicon makes up a huge portion of the material’s elasticity and elasticity. It increases the capability of the steel to regain, upon unloading, its original configuration as low-stress deformed steel. Manganese is a key addition that contributes to hardenability and wear resistance. This allows for a homogenous microstructure after heat treatment, critical to having uniform performance from one part to another in various applications.

Chromium, Vanadium, and Molybdenum

Chromium provides corrosion resistance and enhances the toughness of the Alloy Spring Steel. Grain refinement with vanadium leads to enhanced toughness and strength. It also improves resistance to fatigue by making the grain finer. The addition of molybdenum in the material enhances both strength at elevated temperatures and creep resistance. All of these combine to provide protection against severe service environments and thus, keep Alloy Spring Steel performing at its best.

Advantages of Promispecial Alloy Spring Steel

Promispecial Alloy Spring Steel offers numerous advantages, making it a preferred choice for various industrial applications. Its unique properties are a result of precise composition control and advanced heat treatment processes.

Tensile Strength and Elasticity

The high tensile strength of Promispecial Alloy Spring Steel makes it resist permanent deformation under substantial loads. This property is very important for those parts that work under more stress. Furthermore, the material has a fantastic elasticity and it can bounce back into its former shape after being put under stress. The combination of tensile strength and elasticity means that parts produced from this material can operate reliably over very demanding conditions.

Fatigue Resistance

Fatigue Resistance is another important benefit of Promispecial Alloy Spring Steel too. It is well suited to use in components that go through cyclic loading for an extended time as the material does not fail under such conditions. This increases the working life and reliability of springs and other elastic elements resulting in less frequent replacements and maintenance.

Consistency and Precision in Manufacturing

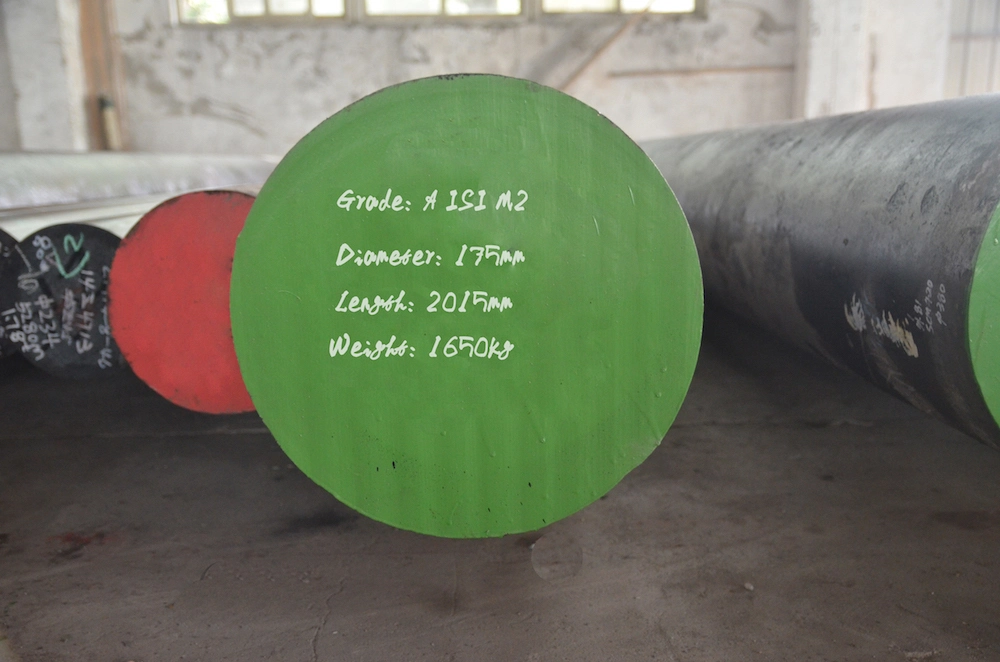

Promispecial Alloy Spring Steel is manufactured with exact consistency. Carefully controlled chemical composition and a highly uniform microstructure, due to advanced processing technique that provides consistency between batches of material that conform to the most demanding specifications. This allows for predictable performance across different applications and gives engineers peace of mind that the material will be reliable.

High-Temperature Resistance

Promispecial Alloy Spring Steel retains its mechanical properties even in high-temperature environments, thus providing optimum performance. Introducing certain alloying elements improves resistance to thermal degradation, allowing the material to remain functional at elevated temperatures. After alloying with proper elements, it shows that this material maintains high resistance to thermal decomposition at high temperatures.

Where Promispecial Alloy Spring Steel Can be Applied

The versatility of Promispecial Customized Alloy Spring Steel allows it to be used in a wide range of applications across various industries.

Various Types of Springs

Springs are one of the primary applications for Spring Steel due to its superior mechanical properties.

- Coil Springs

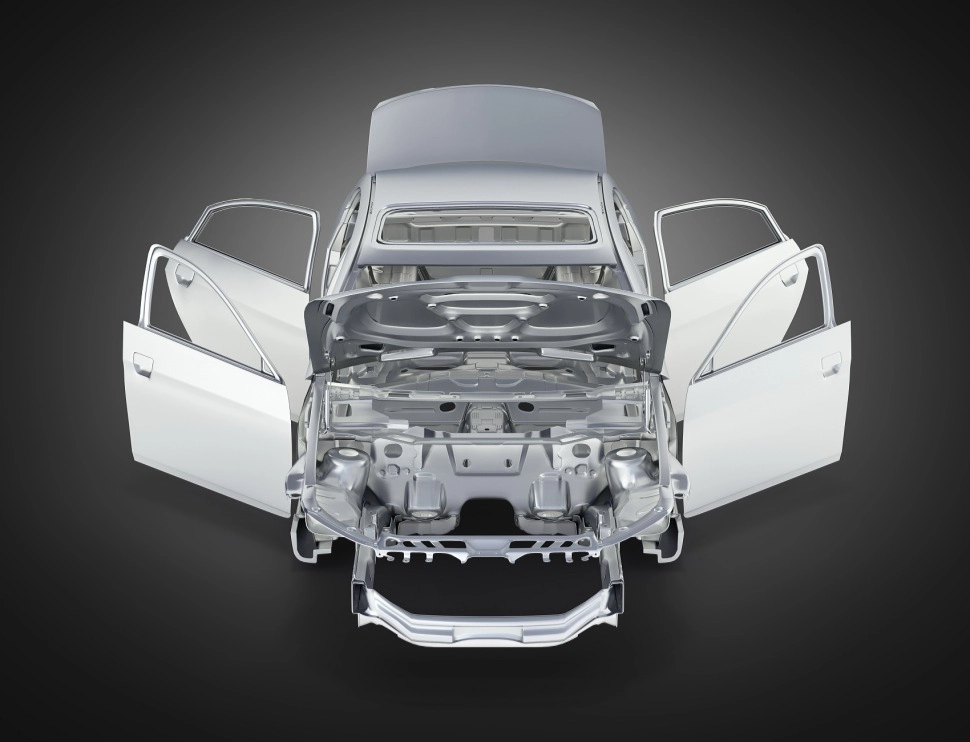

Coil springs made from this material provide exceptional performance in automotive suspensions and industrial machinery. Their ability to absorb shocks and maintain stability under varying loads makes them indispensable in these sectors.

- Leaf Springs

Leaf springs benefit from the high tensile strength and durability of Promispecial Alloy Spring Steel, ensuring reliable performance in heavy-duty vehicles and equipment.

- Steering Springs

In steering systems, springs must offer precise control and responsiveness. The elasticity and fatigue resistance of this material makes it an ideal choice for such critical components.

- Valve Springs

Valve springs require consistent performance under high-frequency loading conditions. The fatigue resistance and high-temperature stability of Promispecial Alloy Spring Steel ensure reliable operation in internal combustion engines.

- High Load Springs

High-load springs produced from this material offer high strength and resilience for applications with heavy loads, such as construction machinery and rail systems. Especially for applications having high loads eg construction machinery, and rail, These material springs provide high-load springs and also provide high strength and stress relaxation.

Rail Fastening Clips

Promispecial Alloy Spring Steel is also widely used in rail fastening clips. The material needs to have high durability to withstand fatigue loads and strains. Learn more about dynamic load and strain so these components wear out over time, and the need to maintain rail alignment under these constant dynamic forces makes the material properties even more important. The durability and fatigue resistance of these parts is critical because they must support constant dynamic forces while continuing to hold the rails in alignment.

Steel Wire Applications

Steel wires made from this alloy are employed in various industries due to their strength and flexibility. They find use in cable systems, tensioning devices, and other applications requiring robust yet pliable materials.

Mechanical Stabilizer Bars

Mechanical stabilizer bars, in automotive suspension systems, need materials with flexibility and rigidity. The properties of Promispecial Alloy Spring Steel enable it to be significant for such components and important for better vehicle maneuverability and stability. Promispecial Alloy Spring Steel is used in these parts because of its properties which enhance the handling and stability of the vehicle.

With the industrial benefits that Promispecial provides, industries can improve product performance and yet remain cost-effective with lesser maintenance and a longer life span. Industries can benefit significantly from the various benefits provided with the help of Promispecial Alloy Spring Steel in terms of better performance and simultaneously economy due to lower wear and tear and long life of components.