What is a Round Steel Bar?

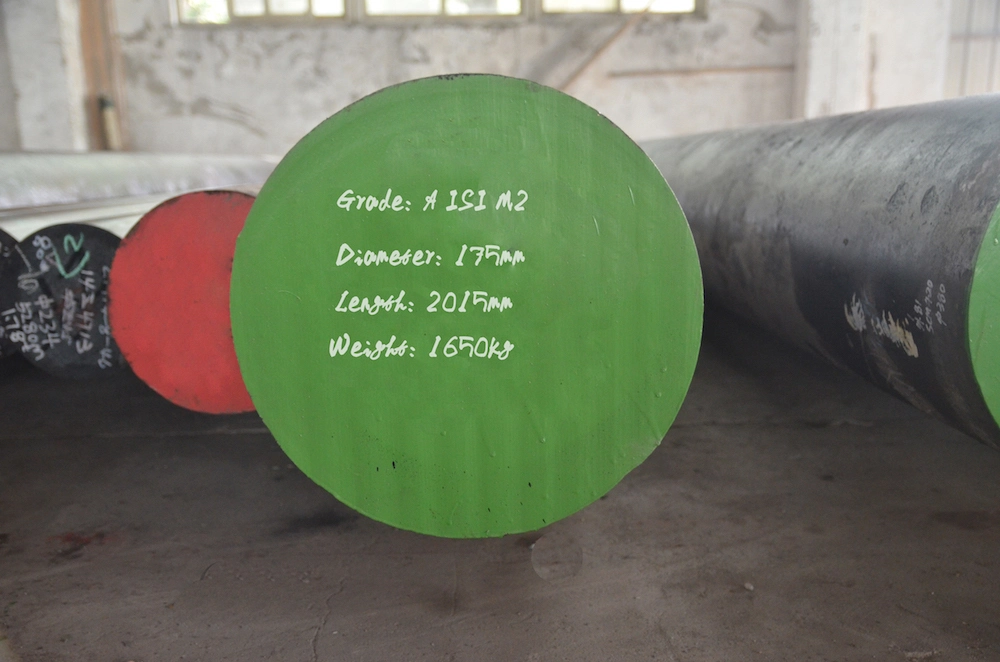

A round steel bar is a long, cylindrical metal bar stock that is widely used across various industries due to its versatility and mechanical properties. These bars are available in a range of sizes, with diameters commonly ranging from 3.0mm to 500mm and lengths from 3000mm to 9000mm. They are manufactured in different finishes, such as bright round bars and hot-rolled round steel, each offering unique benefits based on the application requirements.

Advantages of Round Steel Bar

High Strength

Retail steel bars are known for their skinny power. That is why they Are mostly sought after in industries where structural strength is an issue. This property of bars with high tensile strength means that they can withstand a very heavy tensile load without failing or changing shape, this is what makes them appropriate for load-bearing. This means that these bars can withstand large pressure without any deformation or breakage which makes them suitable for load-carrying applications.

Ductility

One more innovation of round steel bars is their ductility. Specifically, it is its property to be stretched into a wire without rupturing in tensile stress in the plastically deformed region. This feature is altogether essential when it comes to applications that need versatility to withstand fluctuating loads. This property is also so important for applications that require flexible and adaptive designs under different loads.

Durability

One of the prime characteristics of round tins is their durability. They are very durable with good abrasion resistance and high resistance to withstand harsh environments. Its durability means you won’t have to replace or maintain granite paddles as much, so it will save you some money in the long run. Reduced frequency of replacement and maintenance, providing savings in the long run due to this durability.

How Round Steel Bar Enhances Production

Efficient Processing

Round steel bars offer efficient processing capabilities due to their uniform shape and size. This consistency facilitates ease of machining and fabrication, reducing production time and increasing throughput. The availability of common sizes, such as diameters ranging from 20-120mm with lengths between 4000-9000mm, ensures compatibility with standard industrial equipment.

Ease of Welding

The weldability of round bars makes them versatile in production places Various welding methods can be used to join them without losing structural integrity. Its case in welding makes assembly processes easy and leads to quicker turnarounds on projects. Combining this ease of weldability with simple assembly improves and speeds up the overall time to complete projects.

Applications of Round Steel Bar

Construction Industry

In the construction industry, round steel bars play a crucial role due to their strength and durability. They are particularly valuable in bridge construction where corrosion-resistant steel is essential to withstand environmental elements and ensure longevity.

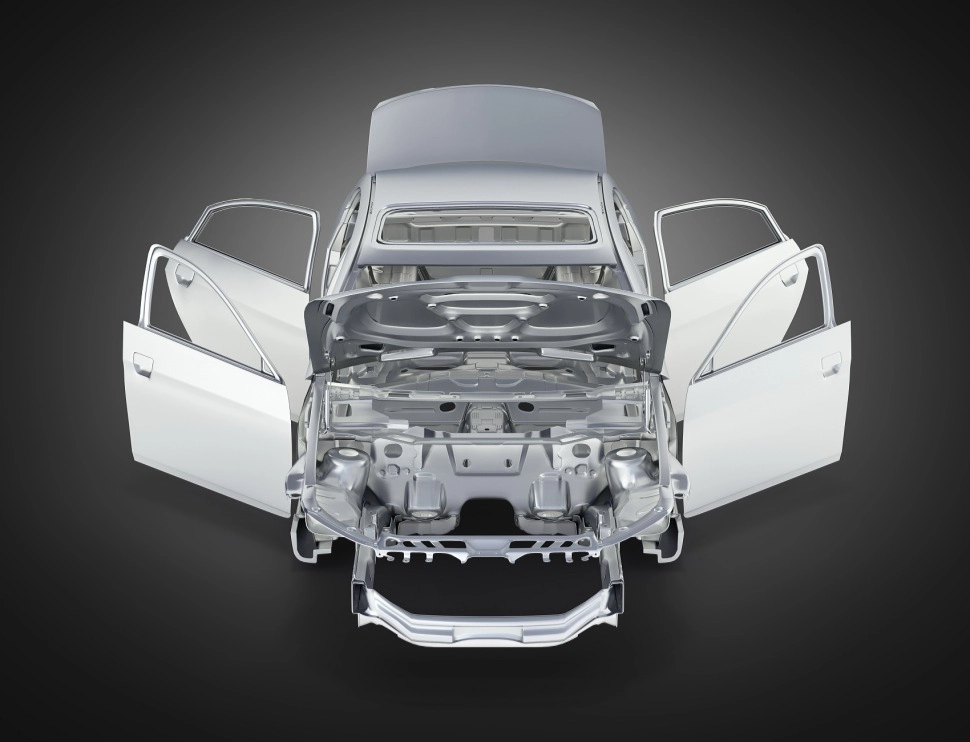

Automotive Industry

Abrasion-resistant steel round barsh, including AR400, AR450 and AR500, help support the automotive industry. The range of lightweight, impact-resistant, and durability, are appropriate for the fabrication of vital products that need high performance, with the added advantage of minimizing vehicle mass and consequently fuel consumption. These traits mean they are great for not only high performance but for reducing the weight of the car which aids in efficiency, a win-win situation for the automotive space.

Marine Shipbuilding Industry

What shipbuilding for the marine industry ship accounts for round steel bar is one of its main raw materials because the material can be resistant to corrosion. They are used extensively in building the hulls of ships and other parts subjected to saline environments where saltwater corrosion is a continual concern.

Machinery Equipment

Wear-resistant steels are also used in machinery equipment, such as bulldozers and other heavy machines, in round bars for durable performance in performing work under harsh operating conditions, enhancing their life span. Wear-resistant steels for machinery equipment, as applied to bulldozers designed for heavy-duty work, are found in round bars to improve strength and longevity under extreme working conditions.

New Energy Applications

For new energy fields such as solar power plants or wind turbine power generation, high-temperature resistant steels and round bar steels are required, such as NM450HiTemp. Such materials guarantee that the components will withstand stages or other environments with extreme temperatures without losing structural integrity or performance efficiency.

Mold Manufacturing Industry

Another precision application related to tool steels that are geared towards mold manufacturing industry needs lies in round bars. The high dimensional accuracy and surface finish quality of these steels are required for fabricating complex shapes of molds employed in plastic injection molding or die-casting processes. Low carbon steels provide a high level of dimension precision and surface finish quality required for the manufacture of complex molds required by plastic injection molding or die casting methods.

Promispecial® Offers Quality Round Steel Bar

Promispecial® is the top manufacturer of round steel bars of great selection to meet the requirements of different industries. These products are free-cutting steel, carbon bearing steel, stainless bearing steel, cold-work mold steel powder metallurgy high-speed steel, etc. Different types of round steel bars are available in multiple sizes and specifications for respective applications.

- Free-cutting Steel

Promispecial® Free-cutting Steel Round Bars has 12mm ~ 500mm diameter (Structured Steel: Ф 50 ~ 1000mm) and Bright Round Bar 3.0mm ~ 25mm diameter (Hot Rolled Round Steel, Bright Round Bar). Our steel bars require minimum to zero machining, making them a great choice for precision and economical applications. These bars make for easy machining and work great for precision and high-utilization applications.

| GB | ASTM/AISI | DIN | JIS |

| Y12/Y12Pb | 12L14 | 9SMnPb28 | SUM24L |

| Y15/T15Pb | 12L14 | 9SMnPb36 | SUM23 |

| Y20 | 1213/1215 | 10S20 | SUM32 |

| Y30 | 1132/1144 | 11SMn30 | SUM43 |

| Y35 | 1137 | 11SMn37 | SUM43 |

| Y40Mn | 1141 | 11SMnPb37 | SUM42 |

| Y45Ca | SUM41 |

- Mold steel

Promispecial® offers mold steel round bars with a diameter of 10mm to 500mm and a length of 3000mm to 6000mm to be used for mold manufacturing. These tools’ steels provide the dimensional precision and surface finish quality required for complex mold making. These high dimensional and surface finish capability tool steel are required for manufacturing complex profiles in molds.

| Cold-Work Mold Steel | ||||

| GB | ASTM/AISI | DIN | JIS | DIN |

| Y12/Y12Pb | 12L14 | 9SMnPb28 | SUM24L | |

| Y15/T15Pb | 12L14 | 9SMnPb36 | SUM23 | |

| Y20 | 1213/1215 | 10S20 | SUM32 | |

| Y30 | 1132/1144 | 11SMn30 | SUM43 | |

| Y35 | 1137 | 11SMn37 | SUM43 | |

| Y40Mn | 1141 | 11SMnPb37 | SUM42 | |

| Y45Ca | SUM41 | |||

| Hot-Work Mold Steel | ||||

| GB | ISO | ASTM | JIS | DIN |

| 5CrNiMo | 4957 (40CrNiMo) | L6 | SKT4 | 1.2713 (40CrNiMo86) |

| 3Cr2W8V | X40CrWMoV5-1 | H12 | SKD6 | 1.2581 (X30WCrV9-3) |

| 4Cr3Mo3SiV | H10 | |||

| 4Cr5MoSiV | 4957 (X37CrMoV5-1) | H11 | SKD61 | 1.2344 (X40CrMoV5-1) |

| 4Cr5MoSiV1 | 4957 (X37CrMoV5-1) | H13 | SKD61 | 1.2344 (X40CrMoV5-1) |

| Plastic Mold Steel | ||||

| GB | ISO | ASTM | JIS | DIN |

| 3Cr2Mo | ISO 4957: 2020 | P20 | SKD61 (H13) | 1.2311 (P20) |

| 3Cr2MnNiMo | 718 | 1.2738 (P20+Ni) | ||

- Carbon-bearing steel

Promispecial® provide carbon-bearing steel round bars in ordinary dimensions which are 20mm to 120mm their diameters and 4000mm to 9000mm their lengths. They are very strong and durable bars which are used for load-bearing purposes. Heavy-duty bars, service load boost, and growing strength of bars suitable for load-bearing applications.

| Carbon Bearing Steel | ||||

| GB | ISO 683-17 | ASTM A866 | DIN | JIS |

| G55 | C56E2 | C56E2 | C55 | S55C |

| G55Mn | 56Mn4 | 56Mn4 | 55Mn4 | S55CMn |

| G70Mn | 70Mn4 | 70Mn4 | S70CMn | |

-300x186.webp)