Common Carbon Spring Steel Grade

| High Quality Carbon Spring Steel | |

| Grade | Application |

| 65, 70, 80, 85 | Widely used in various applications, carbon spring steel is particularly suitable for small springs operating at low temperatures or larger springs that are not highly critical. |

| 65Mn, 70Mn | It is commonly employed in the production of small-section flat springs, round springs, clock springs, spring rings, valve springs, shock absorber springs, clutch springs, and brake springs. |

What is Carbon Spring Steel

Carbon spring steel is a specific type of alloy meant to yield many forms of springs and other elastic parts with great performance and excellent service life. The composition of this type of steel is usually between 0.62% and 0.90% carbon. Based on manganese content, manganese steel is divided based on two types: standard manganese steel contains 0.50% to 0.80% manganese, and high manganese steel is 0.90% to 1.20% manganese.

The Importance of Carbon Spring Steel in the Industrial Sector

Carbon spring steel plays a crucial role across multiple industries due to its superior mechanical properties. It is indispensable in sectors such as automotive, industrial machinery, agriculture, and aerospace for manufacturing suspension springs, valve springs, and other critical components requiring high reliability and performance under extreme conditions.

Production Process of Carbon Spring Steel

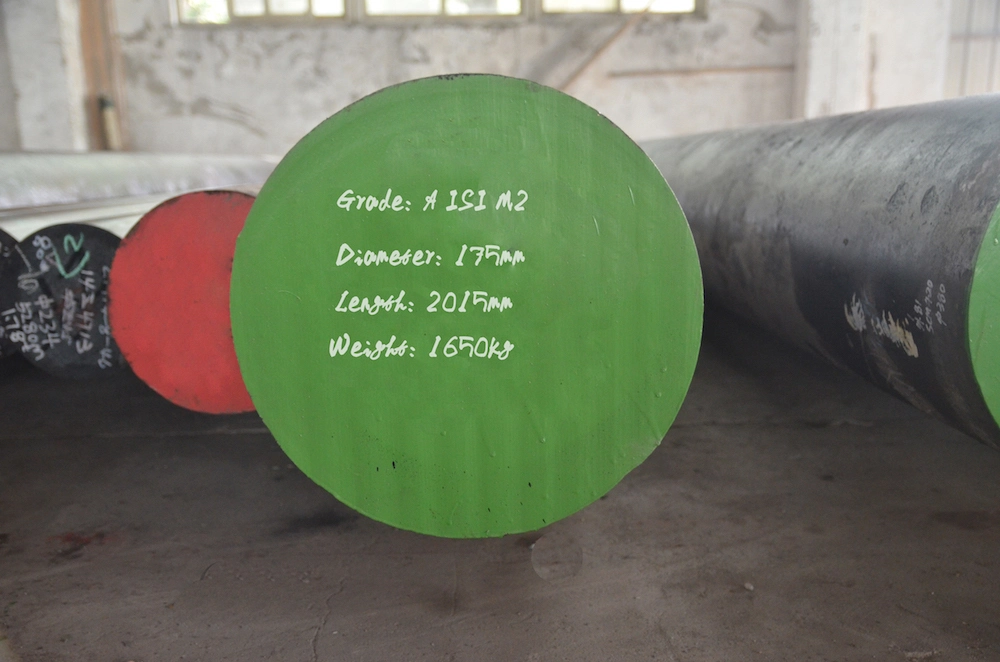

Melting and Casting

Carbon spring steel is produced by melting the raw materials in high-temperature furnaces to form a molten metal. This liquid steel is then poured into molds to produce either ingots or continuous casting billets which subsequently become the input to further processing. They then cast this molten steel into either ingots or continuous casting billets which are the feedstocks for additional processing.

Hot Rolling

Hot–rolling is the next phase for the steel, after being cast, it is reheated into the hot rolling zone above its recrystallization temperature and then passed through coefficient rollers to get a thinner shape and improve its mechanical properties. It is then cooled under controlled conditions to obtain the desired microstructure. The hot-rolled steel is cooled under controlled conditions to achieve the preferred microstructure.

Cold Rolling

Some applications cold draw or cold roll the hot–rolled steel. Cold drawing is one, where the cross-sectional area is reduced by pulling through a die, leading to a change in mechanical properties by enhancing tensile and yield strength while achieving enhanced surface finish and dimensional accuracy.

Heat treatment

Heat treatment is an important process that is carried out to obtain mechanical properties that are required. Initially, the steel is austenitized by heating to ~800°C to 900°C and then quenched in oil or water imparting a martensitic structure, providing good strength and hardness. Then the tempering takes place at about 300°C to 500°C for the reduction of brittleness from quenching while increasing toughness and elasticity.

Surface Treatment and Inspection

Surface quality is guaranteed by shot blasting, pickling, and anticorrosive protection in the form of phosphating or zinc. Surface discontinuities such as decarburization or cracks are painstakingly scrutinized and refined. The finished product is subjected to strict quality control tests like dimensional checks, hardness, tensile strength, and fatigue, as well as non-distractive testing such as ultrasonic or magnetic particle inspection.

Advantages of Carbon Spring Steel

High Tensile Strength

Carbon spring steel exhibits superior tensile strength capable of bearing substantial loads without deformation. This makes it ideal for applications requiring robust materials that maintain integrity under stress.

Superior Elasticity

The elasticity of carbon is characterized by its force for elastic deformation up to the elastic limit. Once this load is removed (by means of a simple periodic force or connector, also called spring), it can carry loads without permanent deformation, that way it is used for springs which should return to their original shape after compression or extension. The mechanism permits it to carry loads while retaining its original shape once the load is removed, so this mode is suitable for springs that need to restore their original configuration upon compression or extension.

Enhanced Fatigue Strength

Fatigue-quality carbon spring steel with improved fatigue strength that extends spring life (if under cyclic loads) This property enables the material to resist impact, vibration, and alternating stress for extended periods, which serves to make it a necessary material in industries where performance must be delivered under difficult conditions. This unique property of impact, vibration & alternating stress withstanding ability for a long time makes it an unavoidable material in such critical industries.

Applications of Carbon Spring Steel

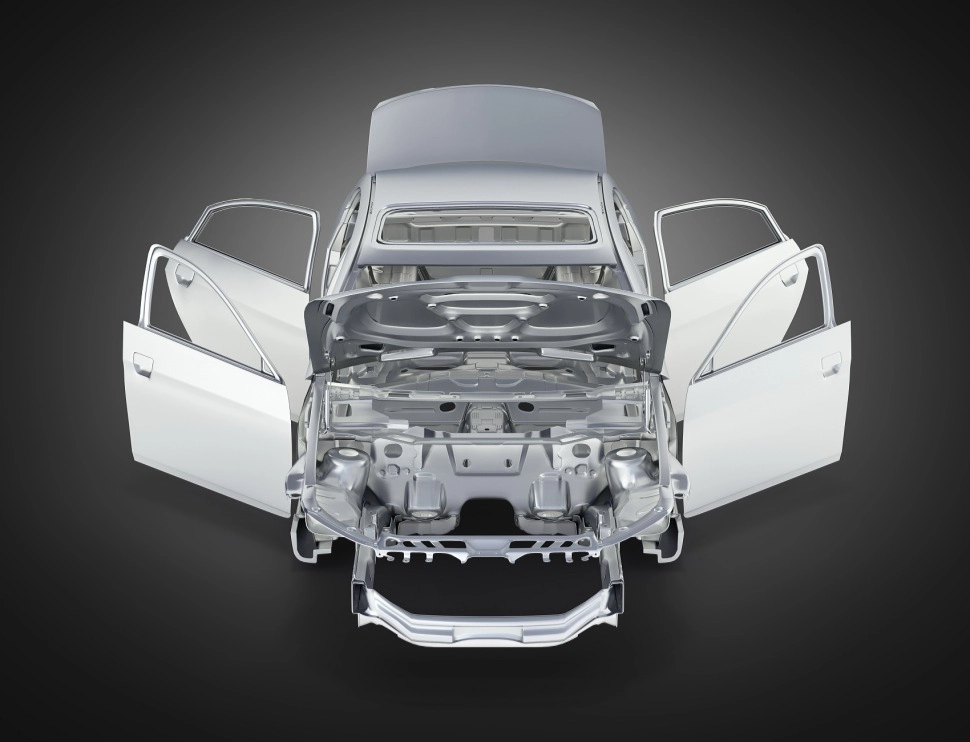

Automotive Industry

Suspension Systems

Among them, carbon spring steel plays an important role in all types of industries; for the automotive industry, carbon spring steel is a critical component of suspension systems. It has high tensile strength and great elasticity, so it is very much used in suspension springs that hold vehicle shock while having good stability. The capability of effectively supporting large loads without changing is what makes these springs guarantee a comfortable ride and improve vehicle handling in several conditions.

Engine Components

Besides suspension devices, carbon spring steel is also broadly utilized in motor pieces, including valve springs. These springs need to have excellent fatigue resistance in order to survive the high-frequency vibrations and repeated stress that they are subjected to during the engine operation. The improved fatigue strength of carbon spring steel extends the life of these key components, ensuring engine performance over time.

Industrial Machinery

Springs and Fasteners

Carbon spring steel is an essential material in industrial machinery for tough springs and fittings. Carbon spring steel high elasticity and tensile strength are important to ensure that these components holds its character and remains functional after continuous strain. Its many elastic deformations without deformation damage ensure a stable function in its corresponding textile processing in a number of heavy industrial ambient systems.

Cutting Tools

Carbon spring steel is also very robust for cutting tools used in industrial applications. That combined with its high hardness and resistance to wear makes it an appropriate choice for blades and cutting tools that need to maintain their sharpness after long-term, high-impact use. The accuracy of spring steel carbon ensures the tool has a perfect dimension and surface to function easily.

Aerospace Sector

Landing Gear Components

Carbon spring steel is employed in aerospace for landing gear parts underneath high-stress and extreme condition environments. The ability of the material to resist impact, vibration, and alternating stress and fatigue helps in the working ability of the landing gear springs under conditions of takeoff, flight, and landing operations. The support that carbon spring steel provides through its high tensile strength is crucial when it comes to upholding aircraft weight while holding its structural integrity.

Structural Parts

Carbon spring steel finds use in different components apart from landing gear, making them ideal for aircraft as well. Likewise, the quality of the metallurgy and consistency of these components guarantees the construction of parts that will meet identical safety standards and high durability and resistance to environmental aggressiveness. Carbon spring steel’s precision engineering lends itself to the aerospace industry’s light but sturdy material makeup.

Promispecial®: Providing High-Quality Carbon Spring Steel

Promispecial® provides expertise in specialized steel products, industry can get access to high-strength materials that improve performance at lower cost. Industries can benefit from Promispecial® expertise in producing high quality spring steel, where tougher materials can foster optimum performance in a given product, whilst being economically priced.

With international certifications like ASTM, EN, JIS, and GB, Promispecial® products are leading in the world market. By providing economy and proficient performance with quality, we become the effective choice for engineering projects across the world. We provide low-cost options without sacrificing performance or quality and are an economical solution for engineering projects worldwide.