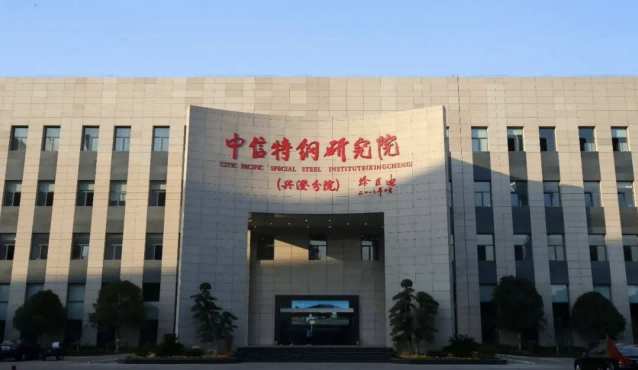

Jiangyin Xingcheng Special Steel, a subsidiary of CITIC Pacific Special Steel Group, has successfully developed the world’s thickest 100mm 9Ni steel for pressure equipment using continuous casting technology. The breakthrough product has passed type certification from nine major international classification societies, including CCS and ABS, shattering the previous thickness limit of 50 mm for classification societies. This achievement not only fills a critical gap in global steel production but also marks a significant advancement in ultra-thick nickel-based cryogenic steels for pressure equipment.

What Is 9Ni Steel?

9Ni steel is a low-carbon martensitic tempered steel developed by the International Nickel Company in 1944. It has excellent toughness and high strength even at cryogenic temperatures and is extensively used in the storage tanks of large-scale LNG (liquefied natural gas). Improvements cannot be brought in much later than 1950, when, again, it came in comparison with austenitic stainless steels or aluminum alloys, offering very low thermal expansion coefficients, greater economic efficiency, and safe use temperatures down to minus -196 °C.

Since 1960, research has shown that post-weld stress-relief heat treatment is not necessary for safe application, further solidifying its position as the primary material for manufacturing LNG storage tanks.

Applications of 9Ni Steel

The basic use of 9Ni steel was in the storage and transportation of LNG, one of the most technically demanding and high-value steel products in the civil market.

- LNG Storage Tanks: With the largest LNG tank capacity in China increasing from 160,000 cubic meters in 2019 to 270,000 cubic meters in 2022, there was a very significant demand for thicker, high-performing steels.

- Marine Applications: Offshore LNG tanks and fuel tanks, usually lower in capacity but for which increasingly thick steel plates are demanded, are making demands on 9Ni steels because they provide a unique combination of strength, toughness, and low-temperature performance.

The trend toward ultra-thick pressure equipment steel is clear, with ongoing construction projects using tank plates as thick as 56mm, exceeding the 50mm limit of current classification society standards.

Technical Challenges and Breakthroughs

Producing ultra-thick 9Ni steel poses significant technical challenges due to its high sensitivity to cracking and stringent low-temperature impact toughness requirements. For years, this field was dominated by foreign manufacturers. However, in recent years, companies like Jiangyin Xingcheng Special Steel and Nanjing Iron & Steel have made substantial progress in localizing production, leading to meaningful applications in domestic and international markets.

By leveraging its extensive expertise in special steel smelting and state-of-the-art equipment, Jiangyin Xingcheng Special Steel successfully developed the 100mm-thick 9Ni steel for pressure equipment. This innovation represents a leap forward in mid-to-thick plate production technology, bringing it to a world-class level and paving the way for the development of high-purity, high-alloy, and high-surface-quality steel products.

Global Significance

This groundbreaking achievement reflects CITIC Pacific Special Steel’s position as a leader in mid-to-thick plate technology on a global scale. It not only underscores the company’s commitment to advancing clean, high-performance special steel but also aligns with global market demands for critical infrastructure materials.

As the world increasingly focuses on sustainable development and advanced manufacturing, CITIC Pacific Special Steel continues to break boundaries and innovate, providing green and intelligent special steel solutions that contribute to human progress.

Visit Promispecial to explore our full range of special steel solutions for demanding applications, including 9Ni steel, tool steel, mold steel, and more!