What is Powder Metallurgy High-Speed Steel (PM HSS)

Powder Metallurgy High Speed Steel (PM HSS) a groundbreaking innovation in tool steel technology is achieved through the use of powder metallurgy processes. PM HSS stands out for its hardness and wear resistance along with its toughness which makes it a top choice for high-performance cutting tools and cold work tools requiring precision and durability, in intricate shapes.

| Powder Metallurgy High-Speed Steel Grade | ||||

| NO. | ASTM | ISO | DIN | JIS |

| 1 | PM M4 | HS 6-5-4 | 1.3346 | SKH54 |

| 2 | PM T15 | HS 10-4-3-10 | 1.3207 | SKH58 |

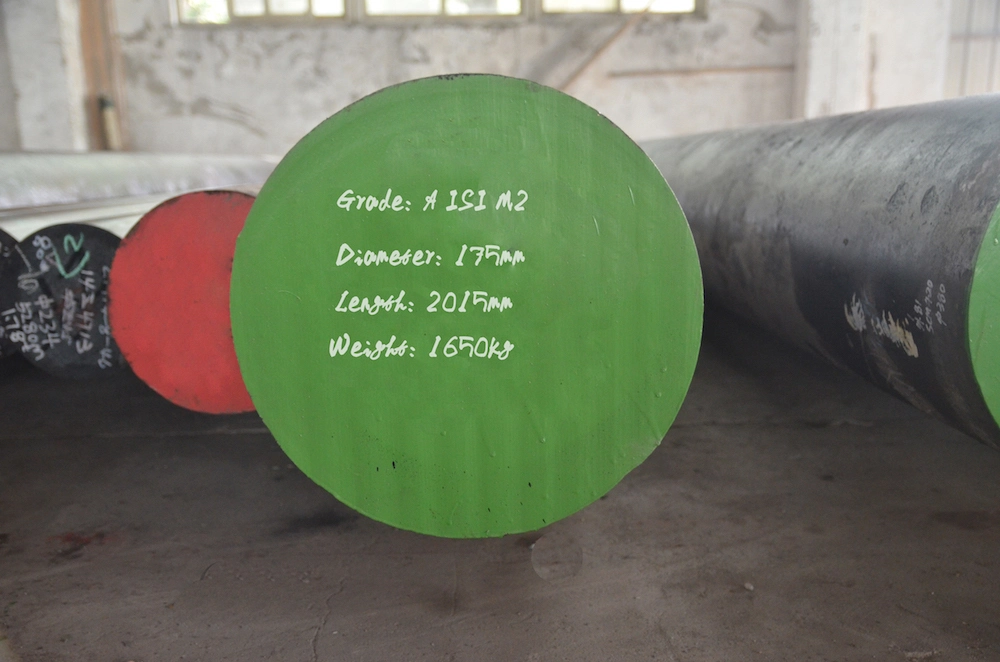

| 3 | PM M2 | HS 6-5-2 | 1.3343 | SKH51 |

| 4 | PM 10V | |||

| 5 | PM S390 | |||

| 6 | PM S290 | |||

| 7 | PM 3V | |||

| 8 | PM M42 | HS 2-9-1-8 | 1.3247 | SKH59 |

| 9 | PM 4V | |||

Comparison with Conventional High-Speed Steel

High-Speed Tool Steel (HSS) is a highly advanced type of tool steel known for its exceptional hardness, wear resistance, and heat resistance. Originally developed by F.W. Taylor and M. White in 1898, HSS revolutionized the cutting tool industry by providing materials capable of maintaining cutting efficiency at high temperatures. Powder Metallurgy minimizes carbide segregation, resulting in more uniform properties and reduced risk of heat treatment distortion.

Characteristics of Powder Metallurgy High-Speed Steel

Uniform Material Properties

Importance of Consistent Microstructure

The creation of PM high-speed steel includes transforming metal into small powder particles that are later compressed and heated to create solid blocks of steel material with consistent carbide particle distribution throughout to remove the usual separation problems seen in traditionally made high-speed steels.

Benefits in Industrial Applications

The even spread of carbides enhances the strength and durability of PM HSS tools, for industrial tasks that require uniformity and reliability.

High Toughness

Mechanisms Contributing to Toughness

PM HSS demonstrates superb strength and durability ideal for challenging uses due to its toughness and resistance, to high temperatures. The removal of carbide separation improves the steel’s durability and ease of machining.

Impact on Tool Longevity and Performance

Enhanced durability plays a role, in the longevity and functionality of tools crafted from PM HSS materials—particularly in settings where dependability is essential.

Superior Wear Resistance

Factors Enhancing Wear Resistance

The even spread of carbide particles in the PM HSS greatly enhances its ability to resist wear, which is essential, for tools used in high-friction environments.

Application Scenarios Benefiting from Wear Resistance

Tools, like end mills and drills, experience advantages from the exceptional wear resistance of PM HSS material which guarantees extended tool lifespan and reliable performance even in demanding situations.

Thermal Processing Capabilities

Heat Treatment Procedures and Effects

The process of heat treatment includes heating and then proceeding with austenitizing followed by quenching and several tempering cycles to attain the desired level of hardness and toughness, in the final product. The Powder Metallurgy process offers enhanced stability by minimizing thermal expansion and distortion during heat treatment processes.

Advantages in Manufacturing Processes

These thermal processing abilities enable adjustment of the mechanical characteristics of PM HSS to support its application in manufacturing procedures, with high precision requirements.

Precision Dimensional Control

Techniques for Achieving Dimensional Accuracy

PM HSS can easily be polished to a surface thanks to its excellent grindability, which is important, for precision tools that require precise dimensions.

Implications for Tool Design and Usage

Tools created with PM HSS are able to uphold measurements when in operation which boosts their performance in tasks that demand a high level of accuracy.

High Alloy Content

Composition Analysis

The increased amount of alloy in the PM method results in the creation of durable high-speed steel materials comprising elements such, as tungsten, molybdenum, chromium, vanadium, cobalt, and more.

Influence on Mechanical Properties

The higher amount of alloy added leads to mechanical characteristics like increased hardness and toughness when exposed to high temperatures making PM HSS a great choice, for industries needing materials that can withstand stress effectively.

Professionals in related fields can gain an appreciation for the benefits of Powder Metallurgy High-Speed Steel by understanding its unique properties compared to traditional high-speed steels. The innovative manufacturing techniques yield materials with performance qualities crucial, for contemporary industrial uses.

Applications of Powder Metallurgy High-Speed Steel

Cutting Tools Industry

Powder Metallurgy High-Speed Steel is greatly appreciated in the cutting tool sector for its durability and resistance to wear and tear. The exceptional wear. The strong endurance of PM HSS guarantees extended tool longevity and reliable functionality rendering it perfect for creating intricate high-performance cutting tools like end mills, drills, taps, and reamers. These tools gain an advantage from PM HSS’s capability to retain sharpness and accuracy, for prolonged durations when compared to tool steels.

Plastic Molds Production

When it comes to making plastic molds PM HSS is a choice for creating parts that need to stay the right size and resist wear and tear. The small grains and evenly spread out carbides, in PM HSS help make it strong so molds can keep their shape. Work well even when they’re put under a lot of pressure.

Aerospace Sector

In the aerospace industry, it is essential to have materials that can endure environments and remain accurate in performance levels over time. There was a supplier of aerospace components who managed to enhance the precision and durability of their top-notch drills and reamers by using PM HSS. This advancement not only saved them costs but also improved the overall quality of their products significantly. PM HSS stands out due to its toughness and ability to withstand high temperatures making it a perfect option for producing turbine blades and other critical components, under intense stress conditions.

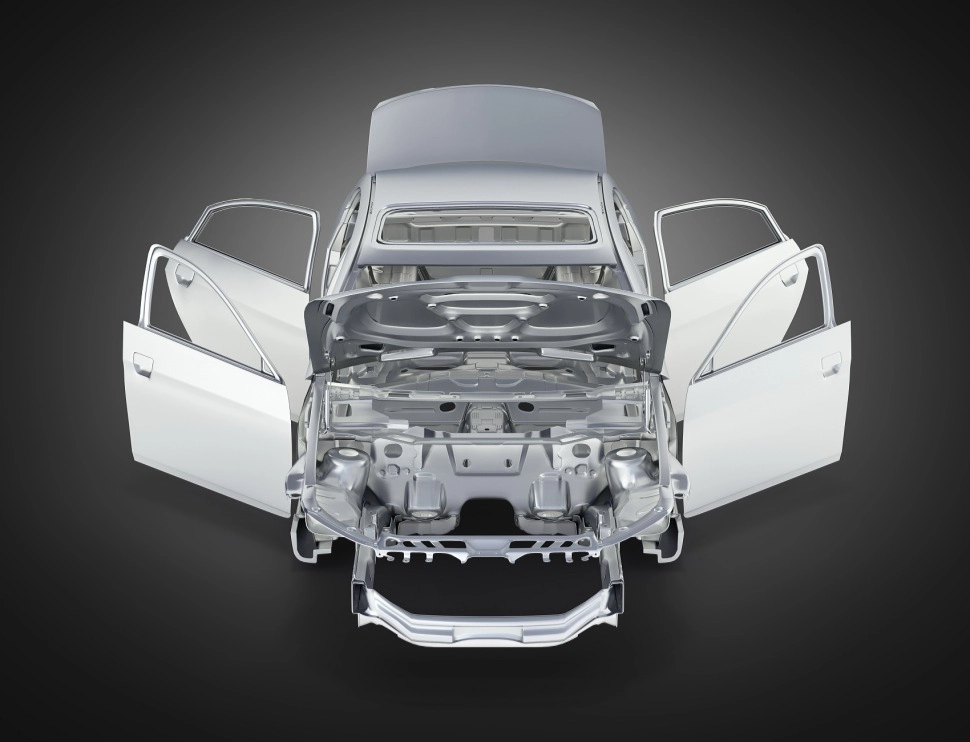

Automotive Industry

The automotive sector gains a lot from utilizing PM HSS in scenarios. A major car manufacturer noted a 50 percent boost in tool longevity and a 30 percent drop in downtime after shifting from HSS to PM HSS, for their cutting tools. This shift showcases the perks of PM HSS’s durability and resilience that help improve production efficiency.

Promispecial® Steel Products Overview

Introduction to Promispecial® Brand

Promispecial® offers cutting-edge steel solutions tailored to meet the needs of high-performance material industries and manufacturing processes today with their top-quality steel products designed to excel in modern production demands.

Product Range and Specifications

Promispecial® provides a selection of tool steel products crafted to excel in a variety of uses and industries. Our product range features custom grades of PM HSS suited to industrial requirements to guarantee customers receive materials, with finely tuned characteristics.