Understanding Corrosion Resistant Steel in Shipbuilding

Characteristics of Corrosion Resistant Steel

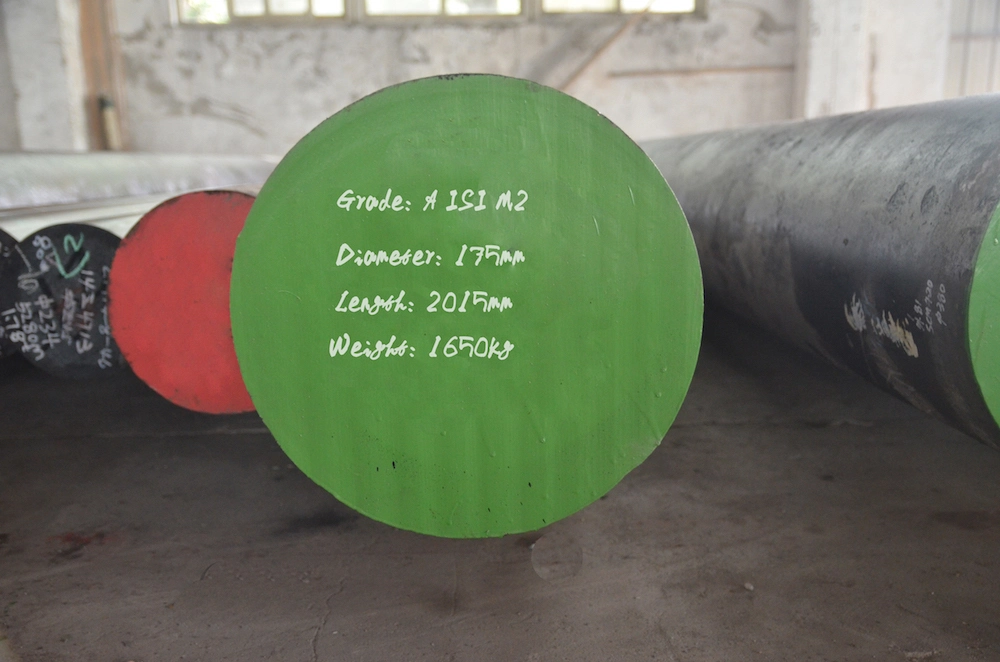

Chemical Composition

Corrosion-resistant steel is engineered to withstand harsh environmental conditions, including exposure to moisture and chemicals. This is achieved through specific alloy compositions that enhance its stability in corrosive environments. Alloy elements such as chromium, nickel, and molybdenum enhance stability in corrosive environments.

Mechanical Properties

The corrosion steel’s mechanical characteristics are crafted to provide longevity and robustness. It maintains performance even in challenging situations, guaranteeing its ability to endure the rigors of marine settings.

Importance in Maritime Industry

Longevity and Durability

In the maritime operations industry, ensuring the longevity and robustness of materials is critical, as they are constantly subjected to environmental conditions over time at sea. Corrosion-resistant steel plays a role in prolonging the lifespan of ship parts by shielding them from deterioration triggered by exposure to salt water and other corrosive substances.

Cost Efficiency

Using corrosion-resistant steel in constructing ships helps lower long-term maintenance expenses by reducing the need for frequent repairs and replacements. This offers a practical and budget-friendly way to uphold the structural durability of the vessel over time.

AH36: A Standard in Shipbuilding Steel

Features of AH36 Steel

Strength and Toughness

AH36 steel is well known for its strength and durability, making it a popular option for different structural uses in the ship construction industry due to its resilience in meeting the rigorous demands of marine vessels.

Weldability

AH36 steel offers a benefit due to its exceptional weldability feature. This attribute makes it easier to construct structures smoothly and efficiently without sacrificing durability or stability.

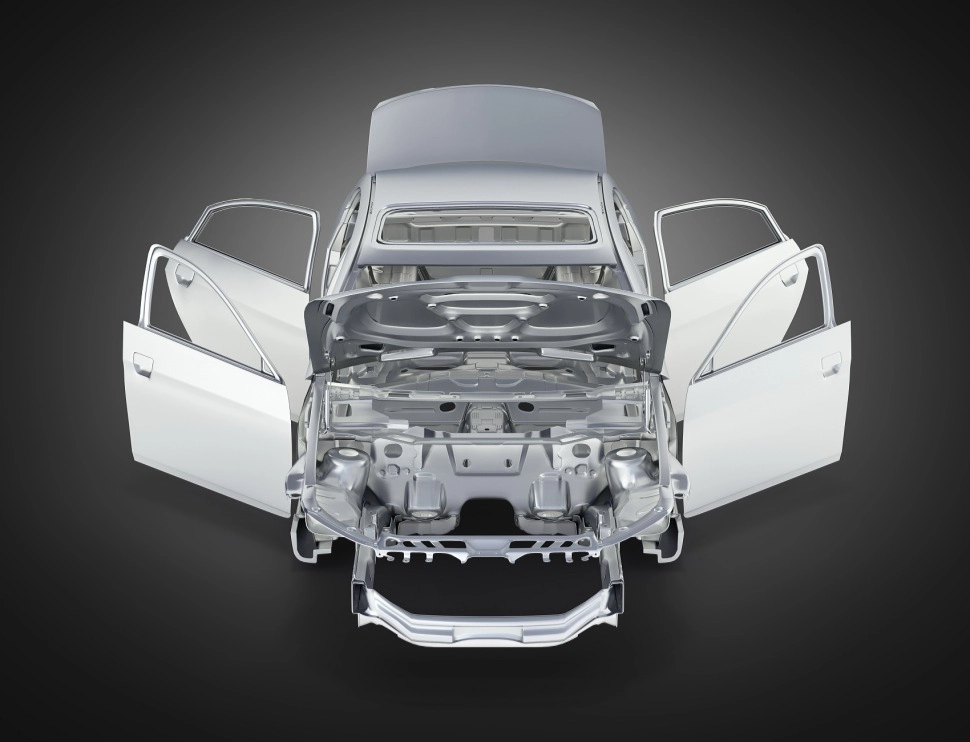

Applications of AH36 in Shipbuilding

Structural Components

AH36 steel is commonly employed in the construction of parts for ships due to its capacity to withstand heavy loads, making it a preferred choice for frameworks that demand strength and durability.

Hull Construction

A ship’s hull is constantly exposed to water and varying weather conditions, which can lead to deterioration over time. However, AH36’s corrosion resistance helps maintain the integrity of the hull for extended periods of time and minimizes the risk of damage or malfunctions.

DH36: Enhanced Performance for Marine Environments

Unique Attributes of DH36 Steel

Higher Yield Strength

DH36 steel boasts a yield strength, in comparison to other grades of steel, which results in improved performance under challenging conditions and heavy loads during the construction of components.

Impact Resistance at Low Temperatures

In settings frequently characterized by chilly temperatures that could impact material functionality adversely, DH36’s impressive durability in cold conditions guarantees dependable performance, even in icy regions where vessels operate.

Utilization of DH36 in Shipbuilding Projects

Offshore Structures

DH36 is a choice for offshore constructions that require strong durability and resistance to impact, as these structures encounter specific difficulties from harsh weather conditions and mechanical strain.

Ice-Resistant Vessels

In the icy seas where ships sail through challenging conditions, DH36 steel offers essential toughness to withstand impacts from ice. Its exceptional mechanical characteristics guarantee that boats can continue operating in the face of harsh environmental challenges.

Promispecial® offers cutting-edge materials, such as NM450HiTemp for situations involving wear and HiAce corrosion-resistant steel for combating moisture and chemical exposure issues effectively on maritime vessels. This boosts their performance and durability in the face of environmental obstacles encountered during sea operations.

HiAce: Advanced Corrosion Resistance Technology

Innovations in HiAce Steel Design

Protective Coatings

HiAce Corrosion Resistant Steel utilizes cutting-edge coatings that greatly boost its resistance to corrosion. These coatings serve as a shield against elements and help thwart chemical processes that might harm the steel material. The creation of these coatings is essential for preserving the durability of maritime ships that face challenging marine environments.

Alloying Techniques

The methods of blending metals utilized in HiAce steel play a role in enhancing its exceptional resistance to corrosion. Through the selection and blending of certain metal elements, like chromium and nickel, the steel’s capacity to endure harsh corrosive conditions is significantly enhanced. These methods guarantee that HiAce steel can withstand long-term contact with moisture and chemicals without sacrificing its integrity.

Benefits of Using HiAce in Marine Applications

Reduced Maintenance Costs

The use of HiAce steel in settings offers a significant advantage through lower maintenance expenses due to its improved resistance to corrosion issues, which then reduces the frequency of repairs and replacements required by ship owners. This benefit allows fleet operators to manage their resources in a cost-effective manner, which is especially valuable for extensive fleets that incur considerable maintenance costs.

Extended Service Life

HiAce steel provides a lifespan for ships at sea by resisting deterioration as time passes on the water’s surface. Its harsh elements are no match for its protective coatings and innovative alloy-blending methods, ensuring the steel’s resilience stands strong even amidst constant exposure to corrosive forces. This results in fewer interruptions in maritime activities and enhanced dependability for shipping firms.

Promispecial® Special Steel Products

Overview of Promispecial® Offerings

Promispecial® is well known for offering steel solutions that cater to a variety of industrial requirements. We offer a selection of high-quality steels that are tailored to tackle specific challenges encountered in different sectors. Through our product range, Promispecial® is committed to delivering steel solutions to customers worldwide.

Advantages of Choosing Promispecial® Steels

Promispecial® provides top industry specialized steel materials. The manufacturing process involves cutting-edge equipment and rigorous quality checks to meet both industry norms and customer needs. We utilize production tools and a stringent quality assessment system to guarantee that each item adheres to industry standards and meets customer demands.

Through the use of cutting-edge technologies like NM450HiTemp, designed for situations involving high levels of wear, and corrosion-resistant HiAce steel called Promispecial®, the company is actively tackling key challenges related to wear and corrosion issues faced in various industries such as shipbuilding, automotive manufacturing, and mining equipment applications.

By utilizing these materials strategically, Promispecial® guarantees that their products not only meet but also surpass expectations in terms of performance and durability. Our dedication to creativity establishes them as pioneers in providing state-of-the-art special steel items crafted to endure the toughest operational conditions.