The Role of Sheet Metal in Automotive Manufacturing

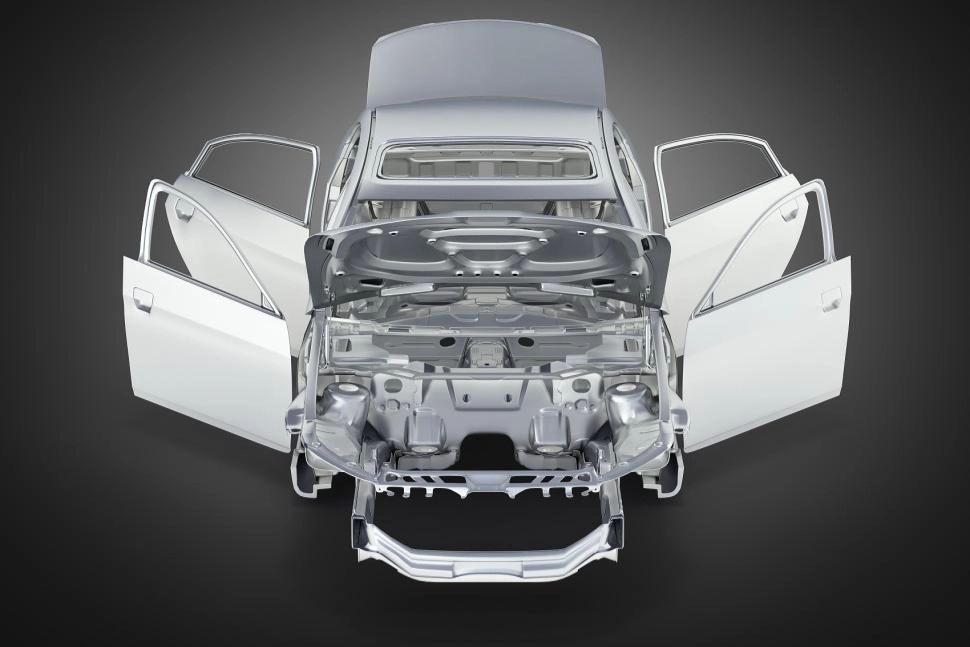

Importance in Vehicle Construction

Metal sheets are essential in building cars because they form the base for parts of the structure and ensure the strength and shape of the vehicle body remain intact and functional, in today’s vehicle designs where complex shapes are crucial.

Contributions to Safety and Efficiency

The incorporation of car metal sheets plays a role in enhancing the safety and performance of vehicles alike. Its capability to absorb impact forces during accidents bolsters passenger safety. Its lightweight nature aids, in enhancing fuel efficiency by lessening…

Aesthetic and Functional Benefits

When it comes to sheet metal technology goes beyond just providing structural support—it also boasts aesthetic benefits by enabling the development of smooth and aerodynamic designs that not only look good but also improve vehicle performance by cutting down drag forces significantly. Additionally it serves a function by furnishing a robust surface that can endure environmental elements ensuring the durability and dependability of vehicles over time.

Types of Sheet Metal Used in the Automotive Industry

Aluminum and Its Applications

Lightweight Properties

Aluminum is commonly preferred in the industry for its lightweight characteristics that improve fuel efficiency by lowering the overall weight of vehicles.

Corrosion Resistance

Aluminum’s inherent ability to resist corrosion prolongs the durability of car components shielding them from rust and deterioration, for outer panels enduring severe weather conditions.

Stainless Steel for Durability

Strength and Resistance to Elements

Stainless steel is well known for its toughness and ability to withstand substances effectively – a perfect choice, for parts that need to last in harsh environments. Its durability guarantees that essential components retain their quality over time.

Use in Exhaust Systems and Trims

Stainless steel is often chosen for exhaust systems, in cars because it can endure temperatures and corrosive exhaust fumes effectively in automotive settings where both durability and visual appeal are important.

Cold Rolled Steel Characteristics

Surface Finish and Hardening Capabilities

Cold-rolled steel provides a consistent surface finish that is ideal for visible parts needing a polished look while also enhancing strength for components, under intense stress conditions.

Applications in High-Stress Areas

Cold-rolled steels’ superior mechanical characteristics make them a perfect choice for high-pressure zones, like suspension elements and frame sections, where strength and functionality are vital.

Fabrication Techniques for Automotive Components

Cutting Techniques in Automotive Sheet Metal

Laser Cutting for Precision Work

Laser cutting is employed for precision work in automotive sheet metal fabrication due to its ability to produce intricate cuts with minimal material waste. This technique ensures high accuracy essential for complex component geometries.

Plasma Cutting for Efficiency

Plasma cutting is a way to swiftly work with thick sheet metal materials while maintaining quality standards in situations where speed is key.

Shearing for Straight Line Cuts

Cutting sheet metal in a line using shearing is a simple method that helps in creating precise cuts, shaping blanks, or removing extra materials before moving on to the next steps of the fabrication process.

Forming Techniques for Shaping Components

Bending Processes and Their Versatility

Crafting techniques enable flat metal sheets to be molded into angles and curves presenting adaptability essential for producing a wide range of car parts, like supports, casings, or structures.

Stamping Methods for Consistency

Methods of stamping guarantee uniformity in manufacturing quantities by employing dies to shape sheet metal effectively a crucial process for producing consistent components such, as car body panels or structural reinforcements.

Joining Techniques in Assembly

Welding Options: MIG, TIG, Resistance

Welding remains a cornerstone technique in assembling automotive sheet metal components. MIG, TIG, and resistance welding each offer unique advantages depending on material type and joint configuration requirements.

Riveting as a Mechanical Fastening Method

Using rivets is a way to securely fasten materials when welding is not an option or not preferred offering sturdy connections that can be easily undone for repairs or maintenance purposes if necessary.

Application of Fabricated Parts in the Automotive Sector

Body Frame Construction

The automotive industry heavily relies on fabricated sheet metal parts for building the body frames of vehicles which act as the core providing safety to passengers, inside the car by absorbing impact energy during accidents and meeting modern design standards effectively with durable components crafted precisely for this purpose. Using manufacturing methods guarantees that every component meets high quality criteria which enhances the overall strength and functionality of the vehicle.

Customization and Upgrades

In the sector as well as among car enthusiasts and manufacturers themselves find great value in fabricated sheet metal parts for customizing and upgrading vehicles to elevate both their looks and performance levels. The customization choices extend to body panels and distinctive trims along with specialized components that showcase individual tastes or specific brand identities. When it comes to upgrades; they often entail swapping out parts with high-performance alternatives that boost aerodynamics or durability while reducing weight. Thanks, to the versatility of sheet metal fabrication techniques; there exists an array of customization options available to cater to different consumer preferences and market trends.

Restoration Projects and Antique Replications

Restoring cars and making replicas of antique vehicles heavily depends on having precise sheet metal parts available for use. Those who restore these cars aim to keep them true to their original form by either finding authentic parts or making new ones with great accuracy. This method includes copying the details and staying true to historical accuracy while using modern methods to guarantee durability and high quality. The flexibility of sheet metal allows artisans to recreate the shapes found in classic designs from the past bringing a fresh perspective, to these enduring classics.

Promispecial® Offers Top Automotive Sheet Metal

Promispecial® is well known for offering high quality automotive sheet metal solutions designed to meet the needs of the industry effectively. We excel in crafting precise products that adhere to strict standards of durability and strength. Utilizing technology and creative methods, Promispecial® products improve vehicle safety, functionality, and visual appeal.

Our dedication to achieving top-quality results is clearly shown in the array of Promispecial® products we offer for different uses in the automotive industry sector. These offerings cater to needs such, as building body frames or engaging in customization and restoration tasks with solutions that aim to enhance the overall standards of automotive production. Promispecial® truly delivers on its promise of excellence through its product lineup tailored towards automotive applications.s

Promispecial® services offer top-notch materials and skilled workmanship to enhance vehicle design and performance progressions using our knowledge for automotive sheet metal, while solidifying our reputation as a dependable ally in achieving manufacturing excellence in the auto industry.

FAQ

Q: What kinds of metal sheets are typically utilized for the exterior of cars?

A: In the automotive sector car frames are made using aluminum or formed steel due to their strength and resistance, to rust.

Q: What is the thinnest metal plate you can get?

A: Metal plates come in thicknesses and can be as thin as 0.2 mm but the minimum thickness needed depends on the material and how its being used.