Automotive Sheet Metal Laser Cutting: Key Applications and Benefits

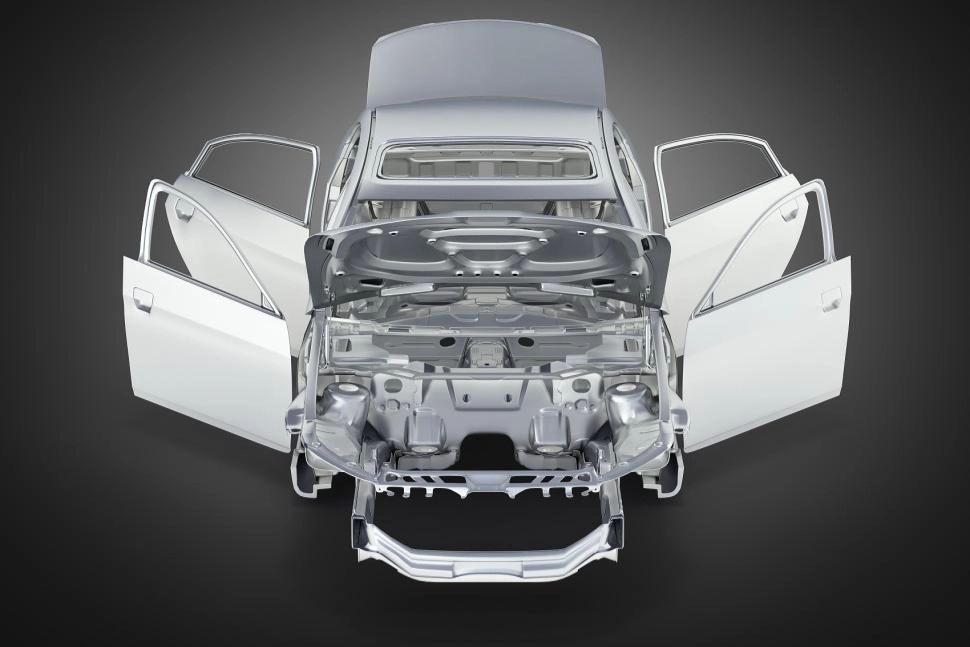

Precision in Body Panels Exterior Body Panel Fabrication Car sheet metal laser cutting is crucial in making outer body panels fit accurately without gaps in the vehicle manufacturing process due, to its precision and accuracy capabilities. Reduction in Finishing Work The use of laser cutting in car manufacturing helps to reduce the necessity for post […]

How Accurate is Automotive Sheet Metal Laser Cutting Technology?

Importance of Laser Cutting in Automotive Steel Manufacturing In the car steel manufacturing sector laser cutting technology is essential. The precision and efficiency of laser cutting systems are unmatched allowing manufacturers to create designs with minimal waste. This technology is crucial in making sheet metal parts, where accuracy and consistency are key. Cutting metals with […]

High Precision Automotive Sheet Metal Blanking: A Detailed Analysis

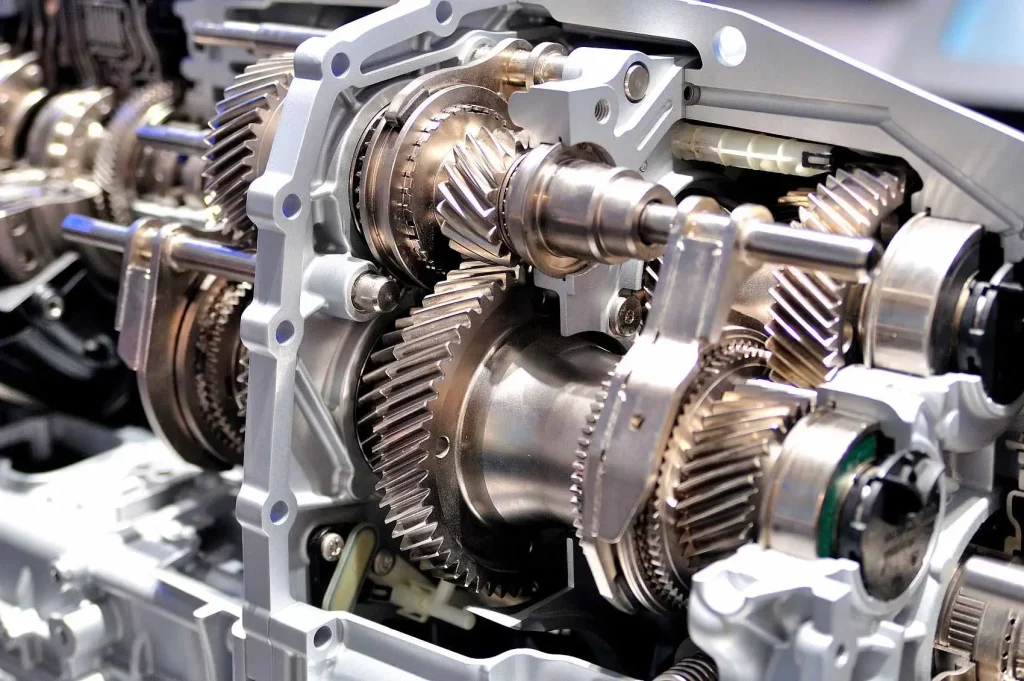

What Is Sheet Metal Blanking Sheet metal blank production plays a role in manufacturing industries like automotive sectors by cutting metal sheets into specific shapes known as “blanks.” These blanks are further processed to create components with dimensions and tolerances for top-notch automotive parts quality consistency is key in this process of producing gears shaft […]

How to Select High Temperature Bearing Steel for Optimal Performance

Understanding High Temperature Bearing Steel Specialized high temperature bearing steel is crafted to endure conditions with a focus on resisting both high temperatures and corrosion in demanding environments. Deployed in heat settings, this stainless bearing steel retains superb mechanical features and exceptional corrosion resistance at temperatures reaching from 200°C to 430°C. It plays a vital role […]

H13, S7: Understanding Hot Work Tool Steel

Tool steel designed for high temperature applications is a type of alloy that maintains its strength and durability under elevated temperatures during manufacturing processes, particularly when tools are exposed to heat and require superior resistance to heat and wear over time. Characteristics of Hot Work Tool Steel Hot work tool steels are famous for their […]

Understanding the Formation of Prestressed Concrete Strands

The Basics of Prestressed Concrete Strands Definition and Purpose In today’s construction industry, prestressed concrete strands play a role in improving the strength and functionality of concrete structures. These steel strands are crafted from high-strength steel and are specially engineered to boost the efficiency of concrete constructions. They are made up of cold-drawn steel wires […]

Understanding Free Cutting Steel: A Guide to Its Grade Specifications

Overview of Free Cutting Steel Definition and Characteristics Free cutting steel, also called machinable steel, is a kind of alloy steel whose machinability is improved by adding certain elements in it. Free-cutting steel, more commonly called machinable steel, is a type of alloy steel that has been designed to enhance its machinability through the addition […]

How to Create Spring Steel: A Comprehensive Guide

High-quality Carbon Spring Steel NO. GB JIS G 4801 1 65 (SUP2) 2 70 3 80 4 85 (SUP3) 5 65Mn 6 70Mn Alloy Spring Steel NO. GB ISO.683-14 EN 10089 JIS G 4801 1 28SiMnB 2 40SiMnVBE 3 55SiMnVB 4 38Si2 38Si7 38Si7 5 60Si2Mn SUP6 6 55CrMn 55Cr3 55Cr3 SUP9 7 60CrMn […]

AH36, DH36, HiAce Corrosion Resistant steel for Shipbuilding

Understanding Corrosion Resistant Steel in Shipbuilding Characteristics of Corrosion Resistant Steel Chemical Composition Corrosion-resistant steel is engineered to withstand harsh environmental conditions, including exposure to moisture and chemicals. This is achieved through specific alloy compositions that enhance its stability in corrosive environments. Alloy elements such as chromium, nickel, and molybdenum enhance stability in corrosive environments. Mechanical […]

Understanding Powder Metallurgy High-Speed Steel: A Comprehensive Guide

What is Powder Metallurgy High-Speed Steel (PM HSS) Powder Metallurgy High Speed Steel (PM HSS) a groundbreaking innovation in tool steel technology is achieved through the use of powder metallurgy processes. PM HSS stands out for its hardness and wear resistance along with its toughness which makes it a top choice for high-performance cutting tools and […]