Understanding Abrasion Resistant Steel

Definition and Importance

Abrasion Resistant Steel, also called wear-resistant steel, this high-strength steel plate is designed to resist large amounts of surface wear and tear in extremely tough conditions. This is mainly its purpose as it must withstand wear and tear as it is being used and thus cannot be replaced, which is why it is one of the vital parts of industries such as mining, construction, or even heavy machinery. The high wear resistance of steel prolongs the service life of equipment, minimizes operational costs, and reliable operation of equipment under conditions of continuous operation.

Steel Grade Overview

The steel grade consists of two parts: the pinyin letter “NM” for “wear resistance” and the specified surface Brinell hardness value. Grades with low-temperature toughness requirements consist of three parts: “NM” and the specified surface Brinell hardness value and quality grade (D, E).

The impact test temperature for D-grade steel is minus 20 degrees Celsius, and the impact test temperature for E-grade steel is minus 40 degrees Celsius.

Chemical Composition and Functionality

The outstanding wear resistance in abrasive Resistant Steel comes from the composition of the steel. The addition of alloying elements such as chromium, molybdenum, and manganese enhances hardness. It results in a heat-resistant microstructure that can endure long-term contact with hard particles/ or rough surfaces.

| Abrasion Resistant Steel Plate Sheet and Strip | |||||||||||

| Grade | Chemical Composition (Mass Fraction) /% | ||||||||||

| C | Si | Mn | P | S | Cr | Ni | Mo | Ti | B | Als | |

| ≤ | ≥ | ||||||||||

| NM300 | 0.23 | 0.7 | 1.6 | 0.025 | 0.015 | 0.8 | 0.5 | 0.4 | 0.05 | 0.0005~0.0060 | 0.01 |

| NM360 | 0.25 | 0.7 | 1.6 | 0.025 | 0.015 | 0.9 | 0.5 | 0.5 | 0.05 | 0.0005~0.0060 | 0.01 |

| NM400 | 0.3 | 0.7 | 1.6 | 0.025 | 0.01 | 1.2 | 0.7 | 0.5 | 0.05 | 0.0005~0.0060 | 0.01 |

| NM450 | 0.35 | 0.7 | 1.7 | 0.025 | 0.01 | 1.4 | 0.8 | 0.55 | 0.05 | 0.0005~0.0060 | 0.01 |

| NM500 | 0.38 | 0.7 | 1.7 | 0.02 | 0.01 | 1.5 | 1 | 0.65 | 0.05 | 0.0005~0.0060 | 0.01 |

| NM550 | 0.38 | 0.7 | 1.7 | 0.02 | 0.01 | 1.5 | 1.5 | 0.7 | 0.05 | 0.0005~0.0060 | 0.01 |

| NM600 | 0.45 | 0.7 | 1.9 | 0.02 | 0.01 | 1.6 | 2 | 0.8 | 0.05 | 0.0005~0.0060 | 0.01 |

PromiSpecial Abrasion Resistant Steel Products

High-Quality Quenched and Tempered Abrasion Resistant Steel

At present, Abrasive Resistant Steel below 6mm is mainly used for lightweight car dump truck cargo compartments, with a minimum specification of 3mm. The advantages of wear-resistant dump trucks compared to traditional dump trucks are: 1. The whole vehicle is lightweight, reducing weight by 50% compared to the 345MPa level; Reduces weight by 33% and energy consumption at 700MPa level; 2. Compared with the original material, it has better wear resistance (increased by 3.5 times), longer lifespan, and less maintenance; 3. Improved the impact resistance of the carriage for different working conditions.

High-toughness and Anti-cracking Abrasion Resistant Steel

The High-toughness and Anti-cracking Abrasion Resistant Steel NM400Tuf-NM500Tuf is the latest upgraded product of a series of traditional Abrasion Resistant Steel. While ensuring the strength and hardness of products of the same level remain unchanged, it greatly improves the impact toughness and can effectively suppress steel plate cracking and crack propagation. It is currently the best-matched Abrasion Resistant Steel for construction machinery in the domestic market in terms of strength and toughness. The impact performance of the NM450Tuf product can reach over 100J at -20℃, which is about 60% -80% higher than traditional Abrasion Resistant Steel and four times the national standard requirement.

Super Abrasion Resistant Steel

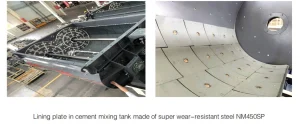

By utilizing the precipitation of superhard TiC particles to enhance the wear resistance of Super Abrasion Resistant Steel, its hardness and mechanical properties are comparable to NM450, and its wear resistance is more than 1.6 times that of ordinary NM450 and more than 1.3 times that of NM550. The task of “domestic extreme thin specification (4 × 2000mm) NM450SP industrial production” in the “13th Five Year Plan” national key research and development project is used to replace high Cr cast iron, which has the advantages of strong ductility and improved wear resistance.

TiC Particle Reinforced Abrasion Resistant Steel

TiC particle reinforced Abrasion Resistant Steel plate has high wear resistance (its wear resistance is better than or the same as that of Hardox450), and it also has good processing and welding performance to meet the manufacturing requirements of related materials during processing. The hardness can be 400-450HB, the tensile strength is 1200-1350MPa, the elongation is 10%-13%, and the impact absorbed work-up to 35J or more at ~20° C; TIC particle reinforced cast high-wear steel plate is used for various equipment and components that require high wear resistance and heavy load; such as excavators, loaders, crushers, ball mills and so on.

It has the characteristics of high strength and high toughness, good stable performance under extreme working conditions, extended service life of equipment, maintenance cost saving, high loading capacity, and long service life in high volume conditions compared with other wear-resistant materials.

Corrosion and Abrasion Resistant Steel

Corrosion and Abrasion Resistant Steel steel is mainly used in industries such as sanitation vehicles, dredging projects, and dredging pipelines. When corrosion wear occurs, the wear performance of materials is affected by corrosion resistance, and simply increasing hardness cannot effectively solve the problem of poor wear performance. This product is based on low-alloy wear-resistant steel, with special ingredients added to increase the self-corrosion potential, reduce the self-corrosion current density, and minimize the promoting effect of corrosion on wear.

High Temperature and Abrasion Resistant Steel

At present, high-temperature and wear-resistant components in industries such as metallurgy and coking in China generally use structures such as ordinary plates and ceramic lining plates. These components have high weight, poor safety, and high cost. High-temperature and Abrasion Resistant Steel can effectively meet the needs of key components in metallurgy and other industries for lightweight, long service life, and cost savings. NM450HiTemp is a High-temperature and Abrasion Resistant Steel plate that provides a cost-effective wear-resistant solution for high-temperature environments ranging from 300-500 ℃.

Abrasion Resistant Steel for Concrete Mixing Drum

NM300TP products can be stably produced to a thickness of 3.0mm, with various indicators such as yield strength ratio and plate shape reaching the leading level in China. Application. The ultra-thin specification and high-strength NM300TP can significantly enhance the core competitiveness of mixer truck products, and the weight of the cylinder can be reduced compared to ordinary trucks 30-40% reduction in welding after adopting an 1800mm wide whole plate, reducing cutting by more than 40%, and lowering manufacturing costs by more than 30%. At the same time, the service life of the carriage is increased by 1-3 times compared to the traditional use of plain carbon steel and high-strength steel, reducing costs during vehicle operation.

High Manganese Wear-resistant Steel

High manganese austenitic steel Mn13, X120Mn12, and Mn12 have good toughness and significant surface work hardening characteristics. Under strong impact or extrusion loads, the stressed surface is work hardened, and the surface hardness can be significantly increased from the initial HB200 level to above the HB750 level, while the steel plate core still maintains good impact toughness. Widely used in mining equipment and machinery manufacturing industries, such as shot blasting equipment, large jaw crushers, etc.

Choose the Most Suitable Steel of PromiSpecial

Versatile Options for Diverse Applications

PromiSpecial abrasion-resistant steels are diverse and tailored for different applications where high temperature, corrosive environment, or extreme abrasive conditions are the case.

Customized Solutions Tailored to Industry Needs

PromiSpecial offers professional customized services in accordance with the specific needs of the clients. Knowing the industry challenges from the inside out, these experts can customize their abrasion-resistant steel products to ensure maximum performance for any application.

Adherence to Stringent Industry Standards

All PromiSpecial abrasion-resistant steel is produced strictly according to industrial standards. This focus on quality assurance ensures that their steel solutions are dependable and uniform, giving clients confidence in using these materials for important applications.

With a focus on quality, customization, and compliance with the highest standards in the business, PromiSpecial is your go-to partner for durable and reliable wear-resistant solutions.

.webp)