Understanding Alloy Special Steel

Special alloy steel is a type of steel known for its exceptional characteristics that are enhanced by incorporating different alloy elements into its composition. These elements are chosen with precision to enhance qualities that make special alloy steel indispensable, in various high-performance uses.

Composition and Properties of Alloy Special Steel

Elements Used in Alloying

Special alloy steel contains elements, like chromium (Cr) molybdenum (Mo) tungsten (Wh), and vanadium (Ve). These components greatly enhance the steel’s ability to harden the toughness of the steel while making it resistant to wear and heat – qualities that are essential for challenging uses.

Mechanical and Chemical Properties

The mechanical properties of alloy special steel are characterized by its exceptional strength, hardness, and durability. The chemical composition allows it to perform well under extreme temperatures and resist deformation. High-Speed Tool Steel (HSS) is a highly advanced type of tool steel known for its exceptional hardness, wear resistance, and heat resistance. This makes it suitable for high-speed operations where conventional steels would fail.

Advantages Of Conventional Steel

Enhanced Strength and Durability

One key benefit of alloy steel compared to traditional steel is its increased strength and durability it offers due to the addition of particular alloying components that improve its hardness and resistance to wear while also enhancing toughness. Qualities essential, for top-notch cutting tools and intricate forms that require both accuracy and lasting quality.

Resistance to Corrosion and Wear

Specialized alloy steel demonstrates durability against corrosion and abrasions which makes it a preferred choice for challenging settings where regular steel would deteriorate rapidly. This characteristic guarantees extended longevity. Decreased upkeep expenses, for parts crafted from this substance.

Applications of Alloy Special Steel in Various Industries

Special alloy steel is utilized in various industries because of its exceptional characteristics significantly improving the performance and dependability of parts, within these fields.

Automotive Industry

Engine Components

In the world of automobiles, alloy special steel finds application in producing engine parts that demand strength resilience, and durability. The use of Promispecial® spring steel proves especially advantageous in such cases thanks, to its outstanding ability to withstand dynamic loads effectively.

Structural Parts

Promispecial® offers wear-resistant steels such as NM400 and NM450 for components, like chassis guards and gears to create lightweight yet strong solutions that improve fuel efficiency and safety standards.

| Steel grade | Executive standard | Approximated products | |

| JFE | SSAB | ||

| NM400 | GB/T 24186~2022 | EH400 | HARDOX400 |

| NM450 | GB/T 24186~2022 | EH450 | HARDOX450 |

| NM500 | GB/T 24186~2022 | EH500 | HARDOX500 |

| NM550 | GB/T 24186~2022 | HARDOX550 | |

| NM600 | GB/T 24186~2022 | HARDOX600 | |

Aerospace Sector

Aircraft Components

The aerospace industry requires materials with mechanical characteristics, for aircraft parts specifically crafted to endure high temperatures efficiently Alloy special steel boasts top-notch hardness and wear resistance guaranteeing optimal performance even under extreme conditions.

Spacecraft Applications

Alloy special steel plays a role, in spacecraft operations by withstanding harsh conditions effectively and ensuring optimal performance even in the most demanding missions where any malfunction is unacceptable.

Construction and Infrastructure

Bridges and Buildings

In infrastructure development like constructing bridges and buildings special alloy steel plays a role in providing the required strength to uphold large structures while also offering durability against wear and protection from corrosion due to environmental factors.

Heavy Machinery

In working conditions, it’s advantageous to employ durable steels such, as Promispecial® AR400 or AR500 in heavy machinery operations to increase the lifespan of equipment by minimizing wear-related issues often seen with lower-grade materials.

Promispecial® has consistently dedicated itself to elevating the reputation of Chinese steel brands by delivering top-notch products under its Promispecial® label that can compete on a global scale. Through the fusion of China’s special steel manufacturing capability and skilled research and development teams, they deliver personalized solutions that meet the precise requirements of clients spanning diverse sectors around the globe.

Promispecial® Provides Top Alloy Special Steel

Promispecial® offers top-notch specialty steel products tailored to meet industrial requirements.

Advanced Manufacturing Techniques

Heat Treatment Processes

Promispecial® utilizes heat treatment methods to improve the quality of alloy special steel focusing on precise temperature regulation and cooling techniques to attain specific mechanical attributes. Alloy tool steel, a steel variant is enriched with alloy elements, like chromium (Cr) molybdenum (Mo) tungsten (W), and vanadium (V) to enhance its properties. Alloy tool steel is crucial in a range of high-performance uses due, to its ability to enhance the hardening capabilities of steel and improve toughness while resisting wear and heat effectively.

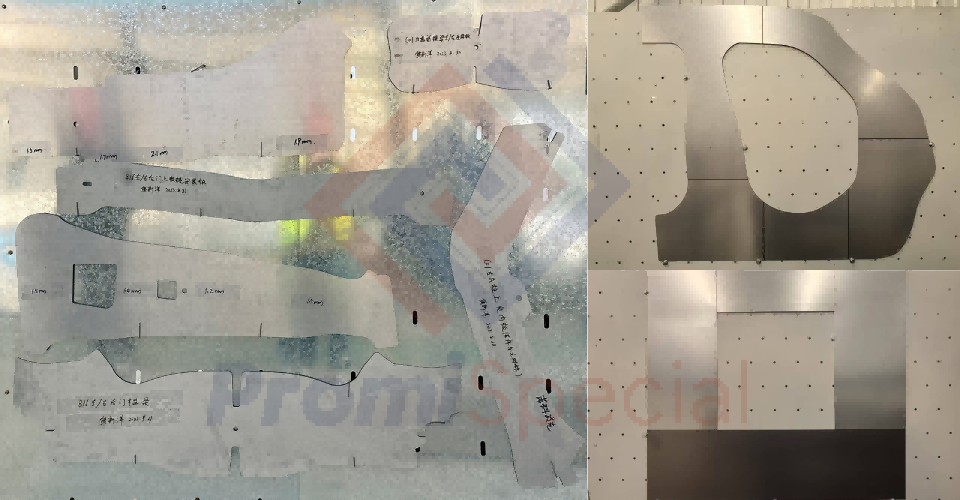

Precision Forging and Casting

Promispecial® employs forging and casting methods to create parts with complex shapes and exceptional durability. This detailed process guarantees that every item meets quality criteria while delivering top-notch performance in challenging situations. Powder Metallurgy High-Speed Steel (PM HSS) an innovation, in tool steel technology provides enhanced properties through the use of powder metallurgy processes when compared to traditional high-speed steels.

Quality Control Measures

Testing and Inspection Procedures

Promispecial® upholds top-notch quality by incorporating testing and inspection protocols at every stage of production to ensure excellence is maintained throughout the process. This includes utilizing invasive testing techniques to detect any possible defects or irregularities in the materials used for packaging. This specialized packaging is crafted to safeguard Promispecial® the special steel range, by Promispecial®, which undergoes meticulous quality checks to guarantee outstanding performance and dependability.

Standards and Certifications

Promispecial® follows standards and certifications to ensure that its products meet high-quality standards worldwide. This dedication to meeting regulations not only ensures top-notch product quality but also boosts customer trust, in their products.Promispecial® is dedicated to elevating the reputation of steel brands internationally and delivering premium Chinese steel goods to industrial users globally.

By combining China’s special steel manufacturing capabilities with skilled research and development groups at Promispecial® they offer personalized services that meet the unique requirements of clients in different sectors around the globe. They are recognized for their commitment to innovation and ongoing enhancement which establishes their status as a frontrunner, in providing high-quality alloy special steel solutions.

Promispecial® offers a variety of products such as mold steel for tooling needs and spring steel for dynamic load settings to meet customers’ specific demands effectively and reliably worldwide thanks to their stringent quality control practices that cement their standing as a reputable supplier of specialized alloy steel items, across the globe.