Introduction

Spring steel and carbon steel are two popular materials in fields like car-making and building. Each has special traits that fit certain jobs. Figuring out how they differ is key to picking the right one for a task. This piece explores their qualities, uses, and what sets them apart.

What’s the Deal with Spring Steel?

Definition and Traits of Spring Steel

Spring steel is a low-alloy, medium-carbon steel famous for its great bounce and toughness. Its standout feature is how it snaps back to shape after bending or twisting. That makes it perfect for tasks needing strength and flex. It holds up well against wear from repeated stress without staying bent. Plus, it has a high breaking point, so it can take big loads without snapping.

Different Kinds of Spring Steel

Spring steel comes in a few types, each made for specific roles:

- High Carbon Spring Steels: These have more carbon, boosting their toughness and pulling strength.If you want to know the top performance of out carbon spring steel, you can check our blog: 65Mn, 70Mn: Understanding Top Quality Carbon Spring Steel.

- Alloy Spring Steels: Stuff like silicon, manganese, or chromium gets added to improve rust resistance and durability.

- Stainless Spring Steels: These mix in chromium and nickel to fight off rust better.

- Oil-Tempered Spring Steels: Heat-treated in oil, they gain extra toughness and bounce.

Common Uses of Spring Steel

Spring steel’s unique perks make it a must-have in many trades. It’s often used to make suspension springs, car leaf springs, saw blades, and parts that face constant up-and-down stress. Its bendiness also works well for flat springs, clips, washers, and even fencing gear.

Key Differences Between Spring Steel and Carbon Steel

Makeup & Production

The big difference between spring steel and carbon steel is what they’re made of. Both start with iron as the main part:

- Spring Steel: Usually has medium to high carbon levels (0.5%–1%) plus a bit of extras like silicon or manganese.

- Carbon Steel: Mostly iron with different carbon amounts—low-carbon types have under 0.25%, medium ones range from 0.25%–0.6%, and high-carbon ones go over 0.6%.

How they’re crafted varies too. Spring steel gets special heat treatments like tempering or annealing to boost its bounce and wear resistance. Carbon steel might skip these steps unless certain traits are needed.

Physical Traits

Spring steel shines with its top-notch bounce and resistance to wearing out compared to regular carbon steel. It’s built to handle repeated stress without staying bent. Meanwhile:

- Carbon Steel: Known for its strength compared to weight but doesn’t flex like spring steel.

- Hardness: High-carbon types can get really tough but might crack under constant pressure.

Spring steel’s knack for bouncing back suits it for moving parts or setups with regular shaking.

Cost & Supply

Carbon steel usually costs less than spring steel. Its simpler makeup and production keep it budget-friendly. You can find it in all sorts of grades for building, machine parts, or tools.

Spring steel’s special qualities often bump up its price. Still, its long-lasting nature can make the extra cost worth it for jobs needing performance under pressure. It might not be as easy to grab as standard carbon steel grades.

Rust Resistance

Rust resistance differs a lot between the two:

- Carbon Steel: Rusts easily in wet conditions unless coated with paint or other shields.

- Spring Steel: Alloyed types, like stainless spring steels, hold up better against rust thanks to chromium or nickel.

For outdoor jobs or damp spots, stainless spring steels beat out regular carbon steels.

Knowing these differences helps engineers and makers choose the right stuff based on what the job needs, budget limits, and weather conditions.

When to Use Which?

Pick Spring Steel

Spring steel is the top pick when bounce and toughness matter most. Its ability to snap back after bending makes it great for moving parts. Trades needing materials to handle constant stress without staying bent often go for it. Take car makers—they use spring steel in suspension setups. Parts like leaf springs need to take steady push and pull.

Its high breaking point lets it carry big loads without cracking. That’s handy for machine parts facing up-and-down stress, like clutch plates or valve springs. Its wear resistance also keeps it solid over time. This makes it a smart buy despite costing more than carbon steel up front.

For outdoor use or wet conditions, stainless spring steels are a solid choice. They resist rust well, ensuring they last in tough spots. Oil-tempered spring steels also shine in jobs needing extra toughness and flex, like tools and cutting blades.

Pick Carbon Steel

Carbon steel is a handy material for projects where low cost and basic strength are enough. Its simpler makeup keeps it cheaper than spring steel. That makes it a favorite in building and general making. Low-carbon types, for instance, work well in beams and pipes. They’re easy to weld and bend.

Medium-carbon steels balance strength and flex. They’re good for machine parts like gears or axles. High-carbon steels, with their toughness and wear resistance, suit cutting tools or strong wires. But carbon steel doesn’t bounce like spring steel. It’s not the best for jobs with constant stress or moving loads.

Coatings or treatments can boost its rust resistance. This makes it usable outdoors or in mildly wet spots. Still, for top performance under pressure or in rusty conditions, spring steel wins despite its higher price.

Promispecial®’s Top-Notch Spring Steel Offerings

Standout Features of Promispecial®’s Spring Steel

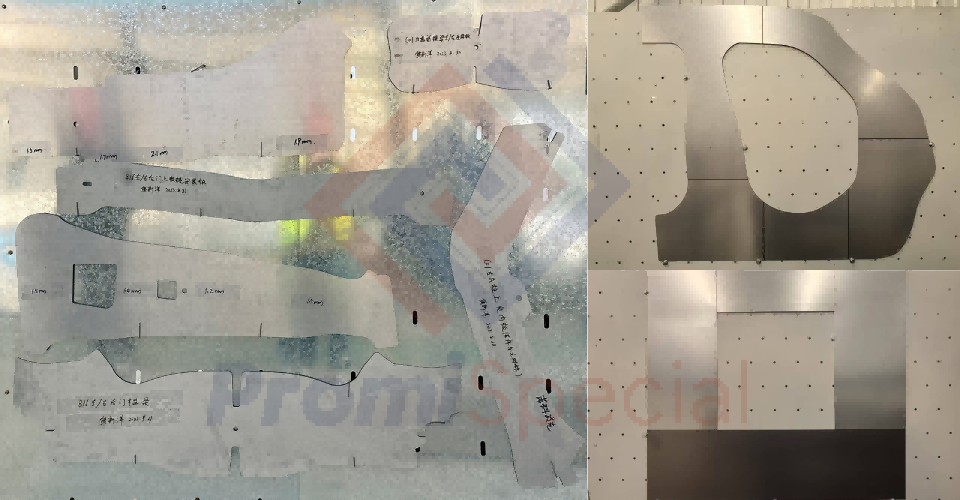

Promispecial® is a big name in high-quality spring steel goods. Their products boast awesome traits tailored to all kinds of industry needs. A key perk is their spot-on mix of ingredients. This ensures steady performance no matter the job.

They use fancy heat treatments like annealing and tempering. These steps ramp up the bounce and wear resistance of their spring steels. It helps them hold up in tough conditions. Their lineup includes options like high-carbon types for max strength or stainless ones for rust protection.

Another cool thing is how precise their products are in size. This cuts waste when shaping them and fits them into existing setups. Plus, Promispecial® cares about the planet. They source materials wisely and use green production methods.

Uses for Promispecial®’s Products

Promispecial®’s spring steel fits a wide range of trades thanks to its flexibility and dependability. In cars, it’s used a ton in suspension setups, clutch plates, and engine parts that need to resist wear. Builders use it for reinforcing bars or tensioned cables where bounce matters.

In factories, their spring steels go into tools like saw blades or chisels that need to stay tough and sharp. They’re also key for making flat springs in switches or clips. These handle loads well. Especially, tailored for demanding applications, alloy spring steel provides a robust and reliable solution for industries requiring high strength and durability.

For special jobs like aerospace parts or medical gear, Promispecial® offers custom fixes to match exact needs. Their stainless spring steels work great in clean or harsh settings with rust risks.

By picking Promispecial®, industries get top-tier materials plus solid tech help. It’s all about boosting performance across different uses from Promispecial®. You can contact us anytime!!

FAQ

Q: Which steel type dominates the automotive lightweighting trend?

A: Spring steel (e.g., SAE 1095) is increasingly favored for suspension systems and seatbelt components due to its high yield strength and fatigue resistance, aligning with lightweighting goals. Carbon steel (e.g., ASTM A36) remains critical for structural frames but faces competition from advanced high-strength steels (AHSS).

Q: How are sustainability regulations impacting material choices?

A: Both steels face stricter environmental mandates. Spring steel’s recyclability (via electric arc furnaces) and carbon steel’s reliance on blast furnaces are under scrutiny. Innovations like zinc-iron alloy electroplating + phosphating (used in carbon steel) aim to reduce hazardous waste.

.webp)