The Basics of Prestressed Concrete Strands

Definition and Purpose

In today’s construction industry, prestressed concrete strands play a role in improving the strength and functionality of concrete structures. These steel strands are crafted from high-strength steel and are specially engineered to boost the efficiency of concrete constructions. They are made up of cold-drawn steel wires twisted together smoothly or with patterns and are mainly utilized in prestressed concrete buildings. Their main function is to enhance the weight-bearing capability and longevity of structures, enabling them to endure substantial pressures and tensions effectively.

Historical Development

Prestressing has changed over the years from its inception to enhance the tensile strength of concrete by applying pre-compression using tensioned steel wires or cables initially to more advanced methods today like high-strength steel strands for large infrastructure projects, thanks to progress in materials science and engineering fields. The shift from reinforcing bars to complex prestressed strands signifies a major achievement in civil engineering that enables the realization of grand architectural designs and structures.

Manufacturing Process of Prestressed Concrete Strands

Raw Materials and Preparation

The process of manufacturing starts by choosing and getting the raw materials ready for use. It is crucial to use top-notch steel when making concrete strands because of its robustness and long-lasting quality. Before using the steel, it goes through testing to guarantee that it meets the precise criteria needed for prestressing purposes, which involves examining for any impurities and ensuring that its mechanical properties are in line with the industry’s requirements.

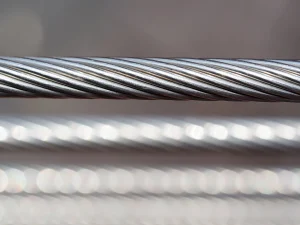

Wire Drawing and Stranding

After getting the raw materials ready for use in the manufacturing process, the steel is pulled through dies in a wire drawing procedure to decrease its diameter and enhance its tensile strength. Next comes the twisting of the drawn wires to create a strand, which plays a role in defining the mechanical characteristics of the end product, such as how flexible it is and how well it handles stress distribution along its entire length.

Stressing and Stabilization

Following being stranded in place after installation, the pre-tensioned concrete strands are put through a process of tensioning to align the arrangement in the steel, which improves its strength properties. After being subjected to tension, the strands are then secured to retain their strength for an extended period without experiencing considerable relaxation or deformation through methods like heat treatment or other stabilization techniques.

Properties and Characteristics of Prestressed Concrete Strands

Mechanical Properties

These prestressed concrete strands showcase mechanical characteristics that render them fitting for challenging construction settings. They possess tensile strength and elasticity while also being resilient to fatigue when subjected to repetitive loads. This composition involves cold-drawn steel wires, either smooth or indented, twisted together. This structural design greatly enhances their capacity to endure loads without experiencing failure.

Durability and Longevity

Prestressed concrete strands are valued for their durability in long-term infrastructure projects due to their ability to withstand hazards like corrosion and wear effectively without compromising their structural integrity over time. This resilience is especially important in scenarios such as bridge construction where safety and dependability are of utmost importance.

Steel strands in prestressed concrete find applications in major infrastructure and building ventures like suspension cables and stay cables for bridges, transfer floors and slabs in tall buildings, reinforcement of containment structures at nuclear power plants, and support systems in tunnels and underground construction projects.

To sum up, the point about how prestressing strands are created gives us an understanding of their important function in contemporary construction methods. With the use of production techniques and upholding strict quality requirements, these durable materials persist in backing novel architectural concepts in diverse global sectors.

Applications in Construction Projects

Infrastructure Development

Prestressed concrete strands play a pivotal role in infrastructure development, providing the necessary strength and durability required for large-scale projects. These strands are integral to the construction of bridges, where they are used as suspension cables, stay cables, and prestressed beams. Prestressed concrete steel strands are widely used in large-scale infrastructure and construction projects, including suspension cables, stay cables, and prestressed beams in bridges. Their ability to handle significant tensile stresses makes them ideal for supporting the substantial loads that bridges must bear over time.

Apart from building bridges, prestressed concrete strands play a role in various infrastructure projects, like tunnels and underground structures. These settings require materials that can endure pressure and withstand environmental wear. The support systems utilized in tunnels and underground construction benefit from the tensile strength and durability of prestressed strands, ensuring the structures last long with integrity intact.

Residential and Commercial Buildings

Prestressed concrete strands play a role in reinforcing the load-bearing capacity of floors and slabs in both residential and commercial building settings. The use of these strands is especially prominent in high-rise buildings where they are employed to create transfer floors that effectively distribute loads across levels. The stability and safety of transfer floors and slabs, in buildings hinge on the mechanical characteristics of prestressed strands that enable them to withstand diverse conditions.

In addition to that point, which was mentioned as well as discussed in detail previously in this conversation thread about the topic we were talking about before now. These specific elements play a significant role in strengthening the containment systems found within the facilities responsible for generating nuclear power electricity for our cities and towns. These components must be able to withstand and remain stable under environmental conditions without any compromise on their overall structural soundness when used in such critical environments. The enhancements made to the containment systems located within nuclear power plants highlight the adaptability and usefulness of stressed concrete strands across various sectors, in the field of construction and development industry.

Promispecial® Products and Application Areas

Product Range Overview

Promispecial® provides special-steel services crafted to suit the requirements of different construction endeavors. We offer a selection of prestressed concrete strands customized for diverse uses to guarantee top-notch performance irrespective of project size or intricacy. Strict adherence to high-quality standards in production allows Promispecial® to ensure that our offerings boast tensile strength, toughness, and longevity.

Industry Applications

Promispecial® products are widely used in industries because of their strong mechanical characteristics and versatility. They play a role in infrastructure projects such as building bridges and supporting tunnels by offering vital reinforcement with their durable steel strands that can handle dynamic forces while preserving structural stability. Engineers rely on these products for their reliability and durability, in demanding applications.

In both commercial construction endeavors, the utilization of Promispecial® strands serves to support creative architectural concepts by effectively spreading loads within intricate building frameworks. This feature not only bolsters structural integrity but also grants architects more flexibility in envisioning elaborate designs.

Understanding the process of creating a prestressing strand allows experts to fully grasp its ranging uses in various areas of the construction field. With a commitment to innovation and maintaining high-quality standards in their products and services, like Promispecial®, companies continue to lead the way in providing materials that contribute to advancements in this industry.

.webp)