Menu

Close

Promispecial®, the premium special steel series by PromiSteel®, undergoes rigorous quality testing to ensure superior performance and reliability.

Quenching is a vital heat treatment process where steel is heated to a high temperature and then rapidly cooled, typically in water or oil. This method significantly increases the hardness and strength of the steel, making it suitable for demanding applications. However, quenching also makes the steel more brittle. To mitigate this brittleness, quenching is often followed by tempering, which helps achieve a desirable balance between hardness and toughness. For industries requiring high wear resistance and durability, quenching is an essential step in the steel treatment process.

Tempering is a heat treatment technique applied to quenched steel, where the steel is reheated to a lower temperature and then cooled. This process reduces the brittleness introduced by quenching while maintaining most of the increased hardness and strength. Tempering is critical for achieving the desired mechanical properties for various applications, such as automotive components, tools, and machinery parts. By fine-tuning the tempering process, Promispecial® steel can be tailored to meet specific performance requirements, ensuring reliability and longevity in its applications.

Annealing involves heating steel to a specific temperature and then slowly cooling it, usually in a furnace. This process softens the steel, enhancing its workability and improving its ductility and toughness. Annealing also helps to relieve internal stresses and refine the grain structure, making the steel easier to machine and more resistant to cracking. For manufacturers, annealing is crucial for producing steel that is both versatile and resilient, suitable for a wide range of industrial applications.

Normalizing is a heat treatment process where steel is heated to a temperature above its critical point and then air-cooled. This technique refines the grain structure, improves mechanical properties, and relieves internal stresses, resulting in a more uniform and predictable material. Normalized steel exhibits enhanced strength and toughness, making it ideal for applications requiring consistent performance under stress. By implementing normalizing, PromiSpecial steel ensures high-quality, reliable steel products for construction, engineering, and manufacturing industries.

With precise guidelines for each specific steel grade, our product labels ensure that your customers understand the proper care and usage of their materials. Promispecial®, the premium special steel series by PromiSteel®, undergoes rigorous quality testing to guarantee superior performance and reliability.

Polishing is a crucial mechanical process that involves smoothing the surface of the steel to achieve a high-quality, reflective finish. Utilizing abrasive materials, polishing not only enhances the aesthetic appeal of Promispecial® steel but also improves its corrosion resistance. This process is particularly valuable for applications where appearance and surface quality are paramount, such as in the production of kitchen appliances, automotive components, and architectural elements. By providing a polished finish, Promispecial® steel ensures both visual excellence and long-lasting performance.

Pickling is an essential surface treatment where steel is immersed in an acid solution to remove scale, rust, and other surface impurities. This cleaning process prepares the steel for subsequent treatments such as coating or plating. For Promispecial® steel, pickling is critical for ensuring a clean, reactive surface that enhances the adhesion and effectiveness of protective coatings. This process is vital for industries that require high-quality, contamination-free steel surfaces, such as chemical processing, oil and gas, and food production equipment.

Galvanizing involves applying a protective zinc coating to steel to prevent rust and corrosion. This can be achieved through hot-dip galvanizing, where the steel is submerged in molten zinc, or electro-galvanizing, which uses an electrochemical process to apply the zinc coating. For Promispecial® steel, galvanizing is an effective method to enhance the durability and longevity of the product, making it ideal for outdoor structures, automotive parts, and construction materials. The protective zinc layer acts as a barrier against environmental factors, ensuring the steel remains rust-free and structurally sound over time.

Coating entails applying a protective layer to the steel surface, which can include paint, powder coating, or other materials. This protective layer shields the steel from corrosion, wear, and environmental factors, significantly extending its service life. Promispecial® steel benefits from advanced coating techniques that provide robust protection while also offering customizable aesthetic options. Industries such as marine, automotive, and construction heavily rely on coated steel to ensure their products withstand harsh conditions and maintain their integrity and appearance over prolonged periods.

Promispecial®, the premium special steel series by PromiSteel®, undergoes rigorous quality testing to ensure superior performance and reliability.

Turning is a machining process where a cutting tool removes material from a rotating steel workpiece, typically to create cylindrical parts and achieve precise dimensions and finishes. For Promispecial® steel, turning is essential in manufacturing components that require high precision and smooth surfaces, such as shafts, bearings, and other rotational parts. This process ensures that the steel meets the stringent dimensional and surface quality standards necessary for high-performance applications.

Milling involves using rotary cutters to remove material from a steel workpiece, typically performed on horizontal or vertical milling machines. This process is used to create complex shapes, slots, and holes with high accuracy. For Promispecial® steel, milling is vital in producing intricate parts and components used in various industries, including aerospace, automotive, and machinery. The versatility of milling allows for the creation of detailed geometries and tight tolerances, ensuring the steel components meet specific design requirements.

Drilling is the process of creating holes in steel using a rotating drill bit, a fundamental machining process used across numerous applications. For Promispecial® steel, drilling is crucial in fabricating components that require precise hole dimensions and locations, such as flanges, brackets, and mounting points. The accuracy and reliability of drilled holes are paramount in ensuring the proper assembly and functionality of steel parts in their respective applications.

Grinding uses an abrasive wheel to remove material and achieve a high-precision finish. It is often employed for finishing surfaces, achieving tight tolerances, and improving surface quality. For Promispecial® steel, grinding is essential in processes where fine surface finishes and exacting tolerances are required, such as in the production of cutting tools, dies, and molds. This process ensures that the steel components have the desired surface characteristics and dimensional accuracy for optimal performance.

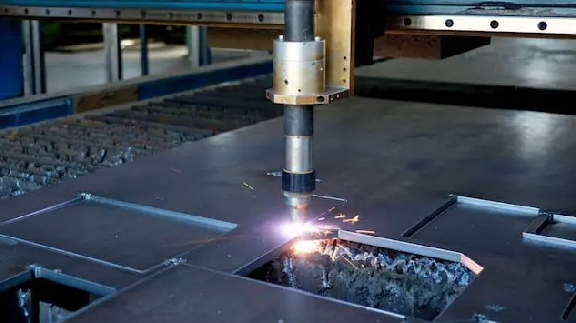

Cutting involves separating steel into pieces using various methods such as sawing, laser cutting, or plasma cutting. This fundamental process in steel fabrication and manufacturing is crucial for shaping Promispecial® steel into the required sizes and configurations. Cutting techniques ensure that the steel meets the specific dimensional requirements for further processing or assembly, enabling the production of high-quality steel components for diverse applications.

Promispecial®, the premium special steel series by PromiSteel®, undergoes rigorous quality testing to ensure superior performance and reliability.

Bright finishing involves polishing and treating the steel surface to achieve a bright, reflective finish. This process not only improves the aesthetic appearance but also enhances the corrosion resistance of Promispecial® steel. By reducing surface roughness and eliminating imperfections, bright finishing ensures a smooth and shiny surface that is visually appealing and durable, making it ideal for applications where both appearance and performance are critical.

Peeling is a machining process where the outer surface of a steel bar is removed using a cutting tool. This process produces a smooth and clean surface, often serving as a preliminary step before further finishing processes. For Promispecial® steel, peeling is essential in preparing the steel for additional machining or coating, ensuring a consistent and high-quality surface that meets stringent industry standards.

Precision grinding is a high-accuracy machining process where material is removed from the steel surface to achieve tight tolerances and a fine surface finish. This process is often used for critical components requiring high precision, such as bearings, gears, and tools. For Promispecial® steel, precision grinding ensures that the final products meet exact specifications and high-quality standards, providing exceptional performance in demanding applications.

Drawing involves pulling steel through a mold to reduce its diameter and increase its length. This process improves the mechanical properties and surface finish of the steel, producing wire, bars, and tubes with precise dimensions. For Promispecial® steel, drawing is crucial in manufacturing components that require high strength, precise dimensions, and excellent surface quality, such as cables, springs, and various structural elements.

Promispecial®, the premium special steel series by PromiSteel®, undergoes rigorous quality testing to ensure superior performance and reliability.

Straightening is a mechanical process used to correct deformations and ensure that steel products are perfectly straight. This process is crucial for applications where dimensional accuracy is paramount, such as in the manufacturing of structural components, shafts, and rails. By eliminating bends and twists, straightening ensures that Promispecial® steel maintains its structural integrity and meets the stringent requirements of precision engineering.

Calibration involves the meticulous adjustment and measurement of steel dimensions to ensure they meet specific tolerances and standards. This process guarantees consistency and accuracy in the final product, which is essential for high-performance applications. By using advanced calibration techniques, Promispecial® steel products achieve the precise dimensions required for critical applications in industries such as aerospace, automotive, and heavy machinery. Calibration not only ensures the reliability of the steel components but also enhances their performance and longevity in demanding environments.

Promispecial®, the premium special steel series by PromiSteel®, undergoes rigorous quality testing to ensure superior performance and reliability., the premium special steel series by PromiSteel, undergoes rigorous quality testing to ensure superior performance and reliability. Our state-of-the-art laboratory is equipped with advanced testing and analysis equipment, guaranteeing that our steel meets the highest industry standards.

– Optical Emission Spectrometer: For precise analysis of chemical compositions.

– X-Ray Fluorescence (XRF) Analyzer: For accurate elemental analysis.

– Infrared Carbon and Sulfur Analyzer: For determining carbon and sulfur content.

– Oxygen, Nitrogen, and Hydrogen Analyzer: For analyzing gas content in steel.

– Microcomputer-Controlled Electro-Hydraulic Servo Testing Machines (30t, 60t, 100t, 200t): For tensile and compression testing.

– Bending Testing Machine: For evaluating bending strength.

– Hardness Testers (Brinell, Rockwell): For measuring hardness.

– Microscope: For microstructural analysis.

– Scanning Electron Microscope (SEM) with Energy Dispersive Spectroscopy (EDS): For detailed surface analysis and elemental identification.

– Sulfur-Chlorine Analyzer: For determining sulfur and chlorine content.

– Gas Chromatograph: For analyzing chemical compositions.

– Industrial Analyzer: For comprehensive industrial analysis.

– Chemical Composition Analysis: Determining the precise chemical makeup of steel and steel-making materials.

– Gas Analysis: Measuring the content of gases such as oxygen, nitrogen, and hydrogen.

– Mechanical Testing: Including tensile, bending, and hardness tests to evaluate mechanical properties.

– Impact Testing: Assessing the toughness of steel at room and low temperatures.

– Microstructural Examination: Using microscopes and SEM to analyze the steel’s microstructure.

– Non-Destructive Testing: Ensuring the integrity of steel without causing damage, including ultrasonic and radiographic testing.

– Coke Industrial Analysis: Evaluating the quality and composition of coke used in steelmaking.

– Alloy Composition Analysis: Determining the composition of ferroalloys and other raw materials.

– Metallographic Analysis: Examining the grain structure and phase distribution in steel.

Ensuring Quality and Reliability

– Precision and Accuracy: Utilization of high-precision instruments and standardized procedures to ensure accurate results.

– Comprehensive Testing: A broad range of tests to cover all aspects of material performance, from chemical composition to mechanical properties.

– Expertise and Experience: A team of skilled technicians and engineers dedicated to maintaining the highest quality standards.

These packaging methods are designed to protect Promispecial®, the premium special steel series by PromiSteel®, undergoes rigorous quality testing to ensure superior performance and reliability. steel from external elements and mechanical impacts, ensuring that it remains in pristine condition until it reaches the end user. Proper packaging not only preserves the quality of the steel but also enhances its appeal by maintaining its appearance and functional properties.

Anti-rust treatment is essential for maintaining the integrity and longevity of steel products, especially in environments prone to moisture and corrosive elements. This process involves applying protective coatings or treatments to prevent rust and corrosion.

Techniques include:

Painting: Applying specialized paints that contain rust inhibitors to create a barrier against moisture and oxygen.

Galvanizing: Coating the steel with a layer of zinc through hot-dip or electro-galvanizing methods to provide long-term protection against rust.

Rust Inhibitors: Using chemical treatments that form a protective film on the steel surface, preventing oxidation and corrosion.

These treatments are critical for ensuring that Promispecial®, the premium special steel series by PromiSteel®, undergoes rigorous quality testing to ensure superior performance and reliability. steel retains its strength and appearance, making it suitable for use in construction, automotive, and industrial applications where durability is paramount.

Proper packaging is vital for protecting steel products during transport and storage, ensuring they arrive at their destination in optimal condition. Effective packaging strategies include:

Wrapping: Using materials such as plastic or fabric wraps to shield the steel from moisture, dust, and physical damage.

Boxing: Encasing smaller steel components in sturdy boxes to prevent deformation and corrosion during shipment.

Bundling: Securing steel bars, pipes, or sheets together with durable straps or bands to facilitate easy handling and reduce the risk of damage.

These packaging methods are designed to protect Promispecial®, the premium special steel series by PromiSteel®, undergoes rigorous quality testing to ensure superior performance and reliability. steel from external elements and mechanical impacts, ensuring that it remains in pristine condition until it reaches the end user. Proper packaging not only preserves the quality of the steel but also enhances its appeal by maintaining its appearance and functional properties.