With the global steel industry having taken a paradigmatic turn, increments of the autonomous special steel section are on a robust path, courtesy of technologically advanced features and a hierarchical industrial system that brings with it progressive innovation. This creates unprecedented incentives for international buyers of steel solutions that are to be relied upon for both performance and quality.

Industry Growth and Market Analysis

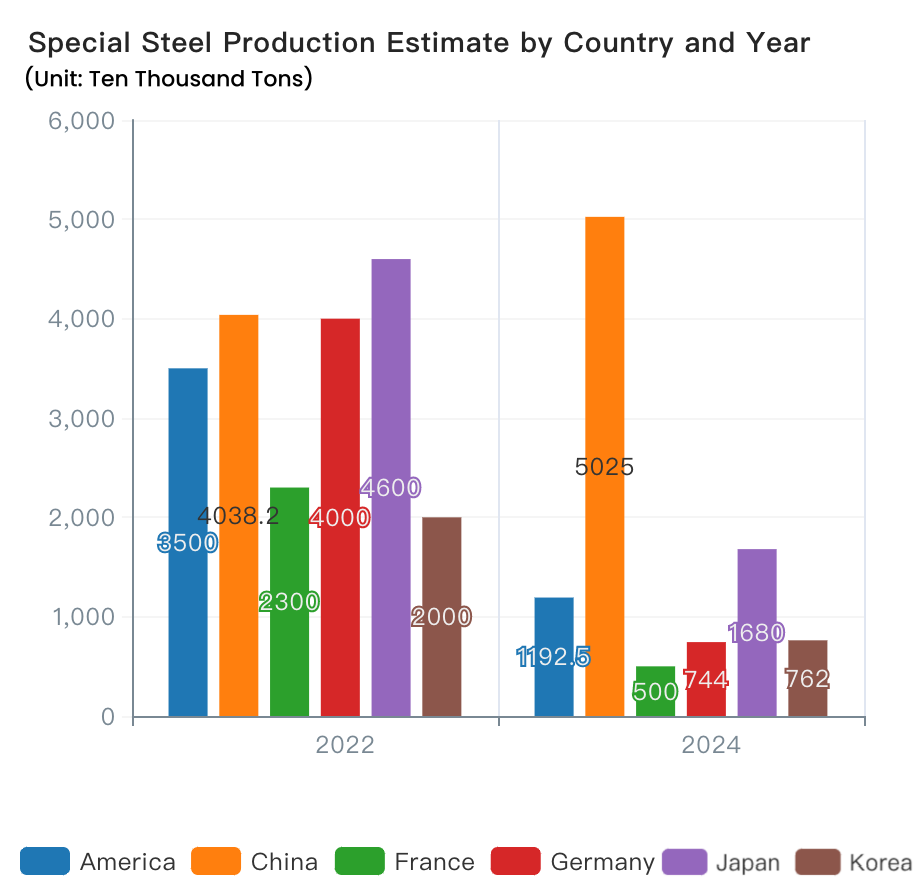

In the recent past, the Chinese special steel sub-sector has seen concrete growth, especially in the sector of alloy special steel, which has gained in production volumes since 2015, despite fluctuating proportions as compared with mainstream crude steel production. By 2020, Chinese crude steel production and its consumption had reached all-time highs, a sign of the resiliency and adaptability of domestic steel enterprises.

Moving forward, the growing market for high-performance special steel is driven by:

- Stainless steel, abrasion-resistant steel, and cryogenic-resistant steel production;

- The share of special steels in total crude steel output is likely to rise to about 15% by 2030, in harmony with developed countries such as Japan and Germany.

- Technology demand from automotive, aerospace, energy, and precision manufacturing grows in high strength, high toughness, and long-life steels.

Government Support and Green Development

The Chinese government introduced a series of policies to promote the upgrade and transformation of the special steel industry. In May 2024, the State Council officially issued the “Energy Saving and Carbon Reduction Action Plan for 2024-2025,” which included the following items:

- Optimization of steel product structures with a focus on high-performance special steel.

- Restrictions concerning the export of low-value raw materials ensure an industry driven by quality.

Concurrently, Chinese specialty steel manufacturers are intensifying their investments in carbon reduction and environmentally sustainable technologies, directing their efforts toward:

- Energy efficiency improvements and pollution control.

- Green material innovationto meet global sustainability standards.

- Advanced process upgrades to support cleaner steel production.

These initiatives directly support worldwide carbon neutrality targets while strengthening the market position of Chinese specialty steel goods in international trade.

Breakthroughs in Special Steel Technology

Innovation remains the key driver of China’s special steel industry. Huge advances were shown at the 2024 China International Special Steel Industry Exhibition:

- Shanghai University and oneHebeiGroup developed 4N-grade high-purity iron and 5N-grade ultra-pure iron, breaking foreign monopolies and solving key supply problems.

- Fangda Special Steel and other top manufacturers are expanding research in new materials, AI-powered steel production, and intelligent manufacturing to enhance product quality and performance.

These breakthroughs reinforce China’s ability to produce world-class special steel materials for critical applications.

Why Choose Chinese Special Steel?

For international procurement professionals, selecting Chinese specialty steel presents distinct strategic benefits:

✅Vertical Integration: China’s vertically integrated industrial ecosystem guarantees end-to-end manufacturing continuity from raw material sourcing to final product delivery.

✅Application-Specific Solutions: Manufacturers offer comprehensive material solutions tailored for transportation equipment, aviation systems, heavy machinery, and renewable energy infrastructure.

✅Cost-Effective Excellence: Precision manufacturing capabilities combined with optimized production processes deliver premium-grade alloys with exceptional cost-performance ratios.

✅Global Market Integration: Through establishing strategic alliances and developing localized service networks, Chinese producers are enhancing worldwide accessibility while delivering customized technical support.

Forging Global Partnerships in Specialty Steel Development

China’s steel innovators are pioneering advanced manufacturing processes, opening new pathways for international cooperation. Procurement executives can now explore partnerships with accredited specialty steel mills to access precision-engineered materials backed by cost-efficient production models.

📢Access certified specialty steel specifications through promispecial.com to streamline your procurement process.

Partner with industry pioneers to create value-driven manufacturing ecosystems and develop eco-conscious supply chains.