Electric Vehicles Reshape Steel Demand: From Volume to Value

The rapid growth of the electric vehicle (EV) market is transforming the automotive steel industry. While EVs use 15-20% less steel per vehicle than traditional cars, high-strength steel and specialty alloys now dominate critical components like battery frames and motors. For steel suppliers and automotive manufacturers, this shift offers both challenges and opportunities. Here’s how your business can adapt—and thrive—in this evolving landscape.

EV-Driven Demand for High-Performance Steel

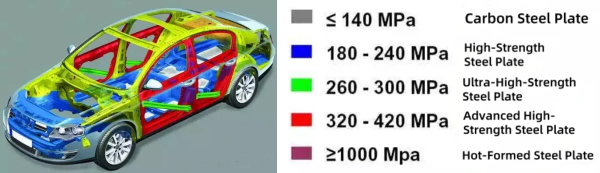

– Lightweighting Without Compromise:

EVs require ultra-strong materials to offset battery weight. For example, 2000 MPa-grade steel (e.g., CITIC Special Steel’s products) reduces battery casing thickness by 20–30% while maintaining safety, cutting overall vehicle weight by 15%.

– New Components, New Markets:

EV-specific parts like motor shafts (using GCr15 bearing steel) and charging piles (304/316L stainless steel) are driving a 10-15% annual growth in specialty steel demand. Companies like Ansteel now deliver customized steel for EV battery frameworks, showcasing rapid market responsiveness.

Winning the Cost-Quality Balance: Innovations in Production

– Tech Breakthroughs:

- Hydrogen Metallurgy: Baowu’s hydrogen-based steelmaking in Zhanjiang cuts carbon emissions by 40%, aligning with global ESG goals.

- 3rd-Gen Automotive Steel: Offers 50% higher strength at only 10% cost increase, outperforming aluminum in cost-sensitive segments.

– Smart Manufacturing:

Benteler China’s automated production lines achieve 150,000 parts/year with 40% lower labor costs. Modular designs (e.g., integrated chassis) reduce part counts by 30%, slashing R&D expenses.

Global Supply Chain Shifts: Where to Invest Now

– Nearshoring Opportunities:

U.S.-Mexico-Canada trade tensions are pushing automakers to relocate production. Mexico’s auto output surged 12% in 2024, creating demand for localized steel suppliers.

– Digital Compliance Tools:

Platforms like Alibaba’s “Global Compliance Assistant” help suppliers navigate tariffs and export regulations—critical for tapping markets like Southeast Asia and the EU.

Why Partner with Promispecial?

At Promispecial, we bridge innovation and practicality:

- Custom Solutions: From 2000 MPa ultra-high-strength steel to corrosion-resistant alloys, we tailor materials for EV makers.

- End-to-end support: leverage our hydrogen-ready steel and smart production expertise to cut costs and carbon footprints.

- Global Compliance: Stay ahead with agile supply chain strategies and digital trade tools.

Ready to lead in the EV steel revolution?

[Contact Promispecial] for lightweight, high-performance steel solutions—engineered for tomorrow’s vehicles.

.webp)